belt clamps

45 posts

• Page 4 of 5 • 1, 2, 3, 4, 5

Re: belt clamps

I made mine out of aluminum and only had a 1/8 inch bit to work with so I knew the channel would be much wider than the belt thickness so I used set screws on the sides to pinch the belts together.

- cybertech99

- Posts: 35

- Joined: Wed Feb 01, 2012 6:07 pm

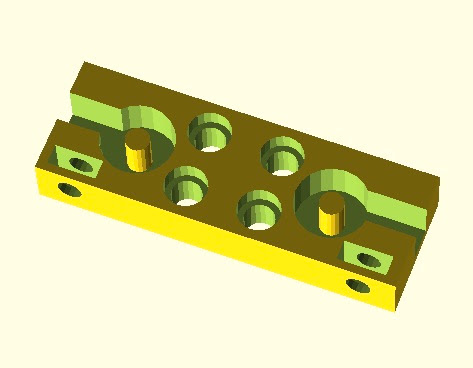

New Design

I just ran out of belt clamps. The loop around was a great idea, but not very robust with respect to belt thickness. I decided to try something new.

This is similar to what I started with, but adds a step feature. The other side is a simple block. It works well and will also support the use of a loop belt. I will need to add (2) extra screws.

This is similar to what I started with, but adds a step feature. The other side is a simple block. It works well and will also support the use of a loop belt. I will need to add (2) extra screws.

Bart

"If you didn't build it, you will never own it."

"If you didn't build it, you will never own it."

- bdring

- Site Admin

- Posts: 2966

- Joined: Sun Nov 22, 2009 7:33 pm

- Location: Chicago, IL, USA

Plastite Thread Forming screws

I am going to start including Plastite thread forming screws with the clamps. These are designed with a sharp, widely spaced thread to cut deep threads into plastic.

You can really tighten these without stripping. I also don't have to tap them anymore.

The spec is #4-20 1/2" long, #1 Phillips drive. Sorry it is not metric, but they will always come with the clamps and if you make your own clamps, you can adjust the hole. O will update the BOM later.

You can really tighten these without stripping. I also don't have to tap them anymore.

The spec is #4-20 1/2" long, #1 Phillips drive. Sorry it is not metric, but they will always come with the clamps and if you make your own clamps, you can adjust the hole. O will update the BOM later.

Bart

"If you didn't build it, you will never own it."

"If you didn't build it, you will never own it."

- bdring

- Site Admin

- Posts: 2966

- Joined: Sun Nov 22, 2009 7:33 pm

- Location: Chicago, IL, USA

Re: belt clamps

Any reason these wouldn't work with the already-shipped kits? I will consider switching these out if they're compatible, cuz I know 2 of my belt clamps are stripped out pretty bad already. Also, what about the Z-axis top nuts, is that the same size screw?

- IPvFletch

- Posts: 127

- Joined: Thu Feb 16, 2012 4:37 am

Re: belt clamps

The Plastite screw holds fine in an M3 tapped hole. You can buy the screws at McMaster

Has anyone stripped the Z nut? Those are much deeper M5 threads. They should not strip unless you are acting like a gorilla on it.

Has anyone stripped the Z nut? Those are much deeper M5 threads. They should not strip unless you are acting like a gorilla on it.

Bart

"If you didn't build it, you will never own it."

"If you didn't build it, you will never own it."

- bdring

- Site Admin

- Posts: 2966

- Joined: Sun Nov 22, 2009 7:33 pm

- Location: Chicago, IL, USA

Re: belt clamps

1 hole (of 4) of my 2 Z nuts has stripped somewhat (just the screw hole where it mounts to the carriage plate, NOT the big hole for the Z lead screw). I can tell because it never got tighter. This was when I very first screwed it in, and I never did re-tighten or loosen or check on it. I know if I yank it out it will be even looser next time. I went SUPER EASY on it and all the delrin pieces (except the feet which aren't tapped and the screw goes THROUGH those) cuz I knew you had said they could strip and they are just delrin/plastic, not metal. It's entirely possible I am not applying ENOUGH pressure to screw it in but I kind of doubt it, and I didn't want to put pressure on it anyways.. If and when I yank it out, I will replace it either with a larger screw like you suggest, or else using loktite or some superglue or something.

- IPvFletch

- Posts: 127

- Joined: Thu Feb 16, 2012 4:37 am

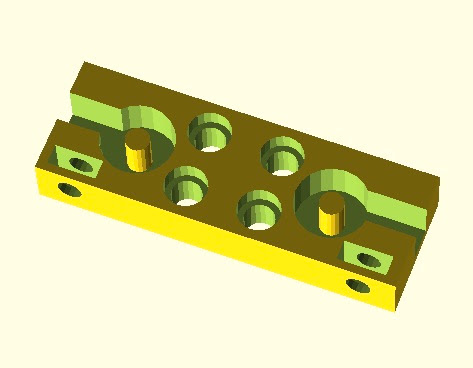

3d Parts!

I really liked the fold over design. With my limited shop it was impossible for me to fabricate the alternate design so I started on my own 3d printed version.

I am pretty happy with my results, granted they are with a Makerbot and not an ORD bot... yet...

seems to work fine with both size belts.

I am use xl size but I threw in a bit of MXL for the photo.

here is some *dirty* openScad code for anyone interested:

I am pretty happy with my results, granted they are with a Makerbot and not an ORD bot... yet...

seems to work fine with both size belts.

I am use xl size but I threw in a bit of MXL for the photo.

here is some *dirty* openScad code for anyone interested:

- Code: Select all

$fn =20;

difference(){

union() {

translate([-10,0,8])cube([59,20,6]);

translate([-10,0,14])cube([59,20,3]);

}

translate([14,0,0]){

translate([0,5,0]) cylinder(r=2.5,h=50,center=true);

translate([0,5,-14]) cylinder(r=3.5,h=50,center=true);

translate([12,5,0]) cylinder(r=2.5,h=50,center=true);

translate([12,5,-14]) cylinder(r=3.5,h=50,center=true);

translate([0,15,0]) cylinder(r=2.5,h=50,center=true);

translate([0,15,-14]) cylinder(r=3.5,h=50,center=true);

translate([12,15,0]) cylinder(r=2.5,h=50,center=true);

translate([12,15,-14]) cylinder(r=3.5,h=50,center=true);

}

difference(){

union(){

translate([4,10,0]) cylinder(r=6,h=30,center=true);

translate([-10,9,0]) cube([13,5,15]);

}

translate([4,10,0]) cylinder(r=2,h=30,center=true);

}

difference(){

union(){

translate([36,10,0]) cylinder(r=6,h=30,center=true);

translate([36,9,0]) cube([13,5,15]);

}

translate([36,10,0]) cylinder(r=2,h=30,center=true);

}

union(){

rotate( [90, 90, 0]){

translate([-12,-4,-3]){

translate([depth/2,0,0])

cube( [8.2, 8, 3.3], center=true );

translate([0,0,-(2.3/2)-5]) cylinder(r=2, h=2.3+5+5, $fn=15);

}

}

rotate( [90, 90, 0]){

translate([-12,43.5,-3]){

translate([depth/2,0,0])

cube( [8.2, 8, 3.3], center=true );

translate([0,0,-(2.3/2)-5]) cylinder(r=2, h=2.3+5+5, $fn=15);

}

}

}

}

- HarveyMoon

- Posts: 8

- Joined: Wed Aug 08, 2012 6:08 pm

Re: belt clamps

That is nice. My original clamps did not work well with various belt thicknesses. You design solves that.

Bart

"If you didn't build it, you will never own it."

"If you didn't build it, you will never own it."

- bdring

- Site Admin

- Posts: 2966

- Joined: Sun Nov 22, 2009 7:33 pm

- Location: Chicago, IL, USA

Re: belt clamps

I received my ORD Bot a few days ago, and started to assemble it.

I'm not very happy with this belt clamp, as it does not pinch the belt enough, letting it move back and forth.

Here is 2 versions of an improved one (I didn't print any yet).

The V1 should automatically pinch the belt as you tighten the 4 screws, because of the 2 little wings on the bottom:

The V2 has an additionnal screw to pinch the belt:

Which one do you think is better?

I'm not very happy with this belt clamp, as it does not pinch the belt enough, letting it move back and forth.

Here is 2 versions of an improved one (I didn't print any yet).

The V1 should automatically pinch the belt as you tighten the 4 screws, because of the 2 little wings on the bottom:

The V2 has an additionnal screw to pinch the belt:

Which one do you think is better?

Frédéric

- fma

- Posts: 213

- Joined: Mon Aug 20, 2012 7:53 am

Re: belt clamps

I find the clamps to work very well. The strength is about where the teeth might start to fail. Are you assembling it correctly? Be sure to apply a little finger clamping of the pieces together as you tighten them.

I think your idea is great, but much more labor to machine. What fabrication process is it designed for?

I think your idea is great, but much more labor to machine. What fabrication process is it designed for?

Bart

"If you didn't build it, you will never own it."

"If you didn't build it, you will never own it."

- bdring

- Site Admin

- Posts: 2966

- Joined: Sun Nov 22, 2009 7:33 pm

- Location: Chicago, IL, USA

45 posts

• Page 4 of 5 • 1, 2, 3, 4, 5

Who is online

Users browsing this forum: No registered users and 44 guests