OrdBot Achievable print quality

Re: OrdBot Achievable print quality

mhensen wrote:I have replaced the threaded rods with ACME leads and I am at this result.. Just a few minor tweaks need to be done..

May I ask where you sourced your lead screws?

- butterfingers

- Posts: 65

- Joined: Thu Feb 16, 2012 8:49 am

Re: OrdBot Achievable print quality

mhensen wrote:This is hopefully an image that tells the 1000+ words

I have replaced the threaded rods with ACME leads and I am at this result.. Just a few minor tweaks need to be done..

Wouhaaaa! Exactly what I expect. Great result. Beautiful.

Would you describe your rig?

A vanilla RAMPS 1.4?

Your soft tool chain?

Slice thickness?

Human has 20 nail ... extruders.

- Digitalmagic

- Posts: 96

- Joined: Wed Apr 18, 2012 9:42 pm

Re: OrdBot Achievable print quality

mhensen wrote:I got them from http://techpaladin.com/ initially for my prusa..

Now it is on my ORD..

Amazing. That's the kind of resolution I'm looking for.

I'd also be very interested in your toolchain, settings, etc., and if you're willing, some details and perhaps a picture of how you integrated the acme screw and nut into the carriage, ie, how did you mount the nut to the carriage?

WB

- WhiteB0rd

- Posts: 60

- Joined: Thu Feb 16, 2012 2:04 am

- Location: South Central PA, USA

Re: OrdBot Achievable print quality

The toolchain is quite simple..

Sketchup or solidworks - save as STL

Slicer settings for me are .175 layer height and .3 infill

Pronterface

Hardware I run is the test version of the X1 Azteeg

The Acme Nut in my case is a cylinder so I took the original nut block and used the measures to create me a new block! That's the purpose of a 3d printer..

An image will come later.. I am redesigning as I am not satisfied!!!!

Sketchup or solidworks - save as STL

Slicer settings for me are .175 layer height and .3 infill

Pronterface

Hardware I run is the test version of the X1 Azteeg

The Acme Nut in my case is a cylinder so I took the original nut block and used the measures to create me a new block! That's the purpose of a 3d printer..

An image will come later.. I am redesigning as I am not satisfied!!!!

- mhensen

- Posts: 45

- Joined: Wed Feb 15, 2012 5:57 pm

Re: OrdBot Achievable print quality

I am very curious to see how you attached your acme screws to your steppers. Also a picture of this acme nut you speak of would be very helpful. I think it's safe to say we would all like to be printing like this. What speed are you printing at. Any chance you could copy and paste your config.ini from slic3r?

Thanks, and good work.

Thanks, and good work.

- mouritsen

- Posts: 10

- Joined: Tue Feb 14, 2012 8:38 pm

Re: OrdBot Achievable print quality

@mhensen - Hey, I also just noticed you have something I need/want. I have the j-head hot end too and I wanted to raise my extruder up just like you have done. Do you have a file I could use to print the same piece?

thanks, again.

Steve

thanks, again.

Steve

- mouritsen

- Posts: 10

- Joined: Tue Feb 14, 2012 8:38 pm

Re: OrdBot Achievable print quality

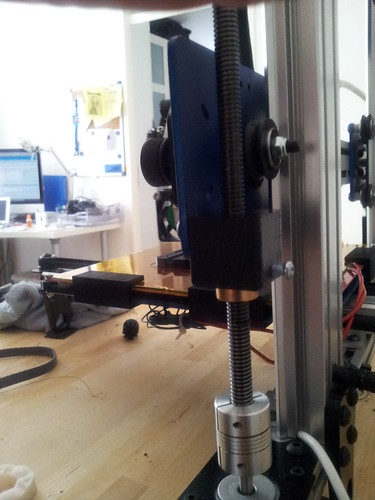

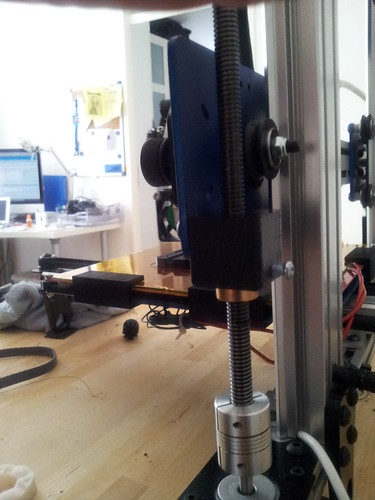

ok .. Here we go.

an image of the acme nut.. ( have a round cylinder instead of a nut..)

Overall view .. then you see the 'nut block' is lower than the x-axis plate.. this to preserve height..

the extruder is bait blurry but that is because it is printing right now

as you might notice .. I am running with the motor on the right..

To print it it is just a matter of switching you x-axis, switch it either in firmware or just rotate the connector, (POWER OFF FIRST) to have 0 on the other side of your printed and run reverse,..

You just need to stop it manually by holding the stop closed as soon as you start the print. Print it and it is inverted no need to mirror an stl file

no need to mirror an stl file

If anybody is wondering what the small blackblock on the left is .. it is my way to make the adjustments to the z-0 height tuning easier

The stls for the nut block and the extruder plate are attached..

Config.ini

I have my perimeters pretty low as this is the outside of the object.. the infill can be higher, even higher as I have right now..But all is pretty basic!

Mind that I use a .35 extruder, in the case of a .5 extruder put the layer height at 0.2 or .25 and the prints are almost as nice!!!!

I hope it helps

acceleration = 0

bed_size = 200,200

bed_temperature = 0

bottom_layer_speed_ratio = 0.3

bridge_fan_speed = 100

bridge_flow_ratio = 1

bridge_speed = 60

cooling =

disable_fan_first_layers = 1

duplicate = 1

duplicate_distance = 6

duplicate_grid = 1,1

end_gcode = G1 X12.0 F4000 ; home (almost) x - stops extruder crashing into frame if at very top of Z height\nG1 Y170 F4000 ; move the print to the front.\nM104 S0 ; make sure the extuder is turned off.\nM140 S0 ; make sure the bed is turned off.\nM84

extrusion_axis = E

extrusion_multiplier = 1

extrusion_width_ratio = 0

fan_always_on = 0

fan_below_layer_time = 60

filament_diameter = 3

fill_angle = 45

fill_density = 0.25

fill_pattern = rectilinear

first_layer_bed_temperature = 0

first_layer_height_ratio = 1

first_layer_temperature = 250

g0 = 0

gcode_arcs = 0

gcode_comments = 0

gcode_flavor = reprap

infill_acceleration = 50

infill_every_layers = 1

infill_speed = 95

layer_gcode =

layer_height = 0.175

max_fan_speed = 100

min_fan_speed = 35

min_print_speed = 10

notes =

nozzle_diameter = 0.35

output_filename_format = [input_filename_base].gcode

perimeter_acceleration = 25

perimeter_speed = 50

perimeters = 3

post_process =

print_center = 100,100

retract_before_travel = 2

retract_length = 1

retract_lift = 0.35

retract_restart_extra = 0

retract_speed = 30

rotate = 0

scale = 1

skirt_distance = 6

skirt_height = 1

skirts = 1

slowdown_below_layer_time = 15

small_perimeter_speed = 35

solid_fill_pattern = rectilinear

solid_infill_speed = 80

solid_layers = 3

start_gcode = G28 ; home all axes\nG92 E0 ;reset extruder\nG1 E3 F1200 ;Prime extruder 3mm\nG1 E2 F1200 ;retract extruder 1mm\nG92 E0 ;reset extruder

support_material = 0

support_material_tool = 0

temperature = 250

travel_speed = 200

use_relative_e_distances = 0

z_offset = 0

an image of the acme nut.. ( have a round cylinder instead of a nut..)

Overall view .. then you see the 'nut block' is lower than the x-axis plate.. this to preserve height..

the extruder is bait blurry but that is because it is printing right now

as you might notice .. I am running with the motor on the right..

To print it it is just a matter of switching you x-axis, switch it either in firmware or just rotate the connector, (POWER OFF FIRST) to have 0 on the other side of your printed and run reverse,..

You just need to stop it manually by holding the stop closed as soon as you start the print. Print it and it is inverted

If anybody is wondering what the small blackblock on the left is .. it is my way to make the adjustments to the z-0 height tuning easier

The stls for the nut block and the extruder plate are attached..

Config.ini

I have my perimeters pretty low as this is the outside of the object.. the infill can be higher, even higher as I have right now..But all is pretty basic!

Mind that I use a .35 extruder, in the case of a .5 extruder put the layer height at 0.2 or .25 and the prints are almost as nice!!!!

I hope it helps

acceleration = 0

bed_size = 200,200

bed_temperature = 0

bottom_layer_speed_ratio = 0.3

bridge_fan_speed = 100

bridge_flow_ratio = 1

bridge_speed = 60

cooling =

disable_fan_first_layers = 1

duplicate = 1

duplicate_distance = 6

duplicate_grid = 1,1

end_gcode = G1 X12.0 F4000 ; home (almost) x - stops extruder crashing into frame if at very top of Z height\nG1 Y170 F4000 ; move the print to the front.\nM104 S0 ; make sure the extuder is turned off.\nM140 S0 ; make sure the bed is turned off.\nM84

extrusion_axis = E

extrusion_multiplier = 1

extrusion_width_ratio = 0

fan_always_on = 0

fan_below_layer_time = 60

filament_diameter = 3

fill_angle = 45

fill_density = 0.25

fill_pattern = rectilinear

first_layer_bed_temperature = 0

first_layer_height_ratio = 1

first_layer_temperature = 250

g0 = 0

gcode_arcs = 0

gcode_comments = 0

gcode_flavor = reprap

infill_acceleration = 50

infill_every_layers = 1

infill_speed = 95

layer_gcode =

layer_height = 0.175

max_fan_speed = 100

min_fan_speed = 35

min_print_speed = 10

notes =

nozzle_diameter = 0.35

output_filename_format = [input_filename_base].gcode

perimeter_acceleration = 25

perimeter_speed = 50

perimeters = 3

post_process =

print_center = 100,100

retract_before_travel = 2

retract_length = 1

retract_lift = 0.35

retract_restart_extra = 0

retract_speed = 30

rotate = 0

scale = 1

skirt_distance = 6

skirt_height = 1

skirts = 1

slowdown_below_layer_time = 15

small_perimeter_speed = 35

solid_fill_pattern = rectilinear

solid_infill_speed = 80

solid_layers = 3

start_gcode = G28 ; home all axes\nG92 E0 ;reset extruder\nG1 E3 F1200 ;Prime extruder 3mm\nG1 E2 F1200 ;retract extruder 1mm\nG92 E0 ;reset extruder

support_material = 0

support_material_tool = 0

temperature = 250

travel_speed = 200

use_relative_e_distances = 0

z_offset = 0

- mhensen

- Posts: 45

- Joined: Wed Feb 15, 2012 5:57 pm

Re: OrdBot Achievable print quality

One other thing for the ones that hade a wobble in the Z-axis is to have the offset nuts quite tight. Give it just enough space that the z-axis motors can push and pull without slipping/skipping. Then loosen the motor mount screws just a bit that the motor mount can slide a bit..

this should help preventing the axis ribbles in you prints..

It is just a suggestion.. I had it running this way before switching to the acme threads..and it made my prints better..Just give it a go .. you can always revert back

This is what we did on the prusa to. the z-motors on top where just laying there with the screws just to hold it in to place but not tight so the motor could move with the wobble a tiny bit

this should help preventing the axis ribbles in you prints..

It is just a suggestion.. I had it running this way before switching to the acme threads..and it made my prints better..Just give it a go .. you can always revert back

This is what we did on the prusa to. the z-motors on top where just laying there with the screws just to hold it in to place but not tight so the motor could move with the wobble a tiny bit

- mhensen

- Posts: 45

- Joined: Wed Feb 15, 2012 5:57 pm

Re: OrdBot Achievable print quality

Thanks, I really appreciate you sharing that with us. My threaded rods and couplers came today. I got threaded nuts, so I've got to figure out how to integrate those into the printer without introducing slop. I was thinking about making a mold of the delrin pieces that come with the ordbot and then casting the nuts in the mold with resin while using the threaded rod as a guide to keep it straight while it sets. If it works I'll put something up here showing it. I'm going to print your raised extruder plate and try some of your settings. Thanks again.

Steve

Steve

- mouritsen

- Posts: 10

- Joined: Tue Feb 14, 2012 8:38 pm

Who is online

Users browsing this forum: No registered users and 19 guests