QU-BD Jams

26 posts

• Page 1 of 3 • 1, 2, 3

QU-BD Jams

OK, so I've got Bart's improvements on my QU-BD extruder including the proper MK7 gear from the guy in Denmark. The fan is on the extruder (its now the loudest part on my machine). I've got another 80mm fan hooked up for cooling the print off to the side of the bed. It heats up nice and quick, and I can push filament through easily. Validedated my e-steps are good, etc. When I test extrusion from Repetier that's fine as well. However…

In my initial testing I found that if I extruded, poked about a bit and went again it would jam. I'd have to back out the filament completely, manually as the gear was just stripping the filament at this point. Try again, good but same result. Looked around on forums and found advice to retract completely after a print. OK, fine. My end gcode now looks like this.

So now I start a print of the octocat, geode generated using cura. Retraction is set to .1 and 40mm/s with a print speed of 80mm/s. 20 mins in it jams. OK. Cool it down, remove the gear but I can't get the filament out. It snaps off in there. Heat it up to 240, 250, nothing. Nothing melts out. I can't push it through either. From what I've read this is heat creep, but why won't what's in there just melt or push out (even using a small allen wrench to account for other filament softening up in the top)?

Any advice on a) getting the nozzle cleaned out and b) what to try next?

I do have another QU-BD all ready to go with the same modifications as I had intended to go dual strusion.

In my initial testing I found that if I extruded, poked about a bit and went again it would jam. I'd have to back out the filament completely, manually as the gear was just stripping the filament at this point. Try again, good but same result. Looked around on forums and found advice to retract completely after a print. OK, fine. My end gcode now looks like this.

- Code: Select all

G91 ;relative positioning

G1 E-1 F300 ;retract the filament a bit before lifting the nozzle, to release some of the pressure

G1 Z+0.5 E-5 X-20 Y-20 F{travel_speed} ;move Z up a bit and retract filament even more

G28 X0 Y0 ;move X/Y to min endstops, so the head is out of the way

G1 E-14 ;retract filament out of tube

M84 ;steppers off

G90 ;absolute positioning

So now I start a print of the octocat, geode generated using cura. Retraction is set to .1 and 40mm/s with a print speed of 80mm/s. 20 mins in it jams. OK. Cool it down, remove the gear but I can't get the filament out. It snaps off in there. Heat it up to 240, 250, nothing. Nothing melts out. I can't push it through either. From what I've read this is heat creep, but why won't what's in there just melt or push out (even using a small allen wrench to account for other filament softening up in the top)?

Any advice on a) getting the nozzle cleaned out and b) what to try next?

I do have another QU-BD all ready to go with the same modifications as I had intended to go dual strusion.

- robotdad

- Posts: 51

- Joined: Thu Sep 09, 2010 7:55 pm

Re: QU-BD Jams

That happens occasionally one one of my units. I think plastic is leaking up and then hardening. When it happens, I disable the cooling fan so the whole nozzle heats. Then I can retract and start again.

Bart

"If you didn't build it, you will never own it."

"If you didn't build it, you will never own it."

- bdring

- Site Admin

- Posts: 2966

- Joined: Sun Nov 22, 2009 7:33 pm

- Location: Chicago, IL, USA

Re: QU-BD Jams

Well that's disappointing to hear. Of course my filament broke off in there so I can't retract it out. I've heated it up to 250 but nada, nothing melts out even with the fan off. On to the next unit for now. Not sure how I'm going to get that stuff out of there.

- robotdad

- Posts: 51

- Joined: Thu Sep 09, 2010 7:55 pm

Re: QU-BD Jams

Swapped out to the second extruder. It jams worse than the first. I can't get more than 5mins out of it.

I was able to get the filament back out this time though, so there is that.

What's the trick here? I've got my esteps set via measuring them without the hot end on. The voltage is a measured 1amp to the extruder. Clearly the hot end is hot enough as it extrudes for at least awhile. I'm printing PLA at 190 (was doing 180 before). I've got bed adhesion.

I'm at a loss.

I was able to get the filament back out this time though, so there is that.

What's the trick here? I've got my esteps set via measuring them without the hot end on. The voltage is a measured 1amp to the extruder. Clearly the hot end is hot enough as it extrudes for at least awhile. I'm printing PLA at 190 (was doing 180 before). I've got bed adhesion.

I'm at a loss.

- robotdad

- Posts: 51

- Joined: Thu Sep 09, 2010 7:55 pm

Re: QU-BD Jams

That style of hot end relies on a very sharp transition in temperature. That's what that part of the barrel with no threads is for -- minimal conducting area. The area just above it should be well connected to a good heatsink.

Check and see if you can print OK without retraction. I've noticed that retraction can "pump" heat back up the barrel.

Check and see if you can print OK without retraction. I've noticed that retraction can "pump" heat back up the barrel.

- BenJackson

- Posts: 522

- Joined: Fri Apr 15, 2011 6:13 pm

Re: QU-BD Jams

PLA or ABS? If it's abs, you can "clean" the head by letting it soak for a few hours in acetone. PLA won't dissolve in Acetone, I usually end up cooking it out with a heatgun...

- SystemsGuy

- Posts: 250

- Joined: Sat Dec 29, 2012 7:44 am

Re: QU-BD Jams

OK, so a report back.

I still haven't cleared the one that jammed with broken filament in the tube. Soon.

The other I've been playing with. I came to suspect my bed. I can't get a reliable level across my bed so I tend to smash the first layer. I decided that might have something to do with it and got the dial indicator back out. It isn't perfect, but its better. Next I did the M303 PID tuning, changed retraction in CURA to .1 and 30mm/s. I also set my e steps to the MK7 value of 100.323 instead of my measured 96.12.

Now I have a cube.

20% infill, smooth sides (thank you z-axis hacks). The top is not closed well though. The filament there is rough and appears to be beading/stringy. I suspect if this had run any longer it would have jammed. This is Ultimaker clear PLA at 190. I think my next step is to try a higher temp. I've also got diamond paste on the way, so I'm going to try polishing at least one of these barrels to see if that helps.

Other suggestions?

I still haven't cleared the one that jammed with broken filament in the tube. Soon.

The other I've been playing with. I came to suspect my bed. I can't get a reliable level across my bed so I tend to smash the first layer. I decided that might have something to do with it and got the dial indicator back out. It isn't perfect, but its better. Next I did the M303 PID tuning, changed retraction in CURA to .1 and 30mm/s. I also set my e steps to the MK7 value of 100.323 instead of my measured 96.12.

Now I have a cube.

20% infill, smooth sides (thank you z-axis hacks). The top is not closed well though. The filament there is rough and appears to be beading/stringy. I suspect if this had run any longer it would have jammed. This is Ultimaker clear PLA at 190. I think my next step is to try a higher temp. I've also got diamond paste on the way, so I'm going to try polishing at least one of these barrels to see if that helps.

Other suggestions?

- robotdad

- Posts: 51

- Joined: Thu Sep 09, 2010 7:55 pm

Re: QU-BD Jams

I've no personal experience with Ultimaker clear, but I did have so Makerbot Clear PLA that was really a pain in the arse to get to print well - my notes say 205c at 105c bed, dropped to 60c after first layer, borosilicate glass surface. I ended up giving the rest of the roll away - I got a few decent prints out of it, but was more trouble that it's worth...

I've said it before, every bit of time you spend squaring and leveling pays of 100x in the long run. I've got my bed level to .05, and my Z Home is set to the same. I usually do the rough leveling at cool temps, and then finish it up with the bed at 100 and the head at 200.

I've said it before, every bit of time you spend squaring and leveling pays of 100x in the long run. I've got my bed level to .05, and my Z Home is set to the same. I usually do the rough leveling at cool temps, and then finish it up with the bed at 100 and the head at 200.

- SystemsGuy

- Posts: 250

- Joined: Sat Dec 29, 2012 7:44 am

Re: QU-BD Jams

Understood on the leveling. I'm seeing variances within the bed though even when corners are level. Just realized tonight that the glass isn't in contact with the pcb at one edge even clamped. The pcb is floating on springs above the ord y bed. So maybe I need a ply edge or something to help keep the PCB level under the glass (window pane, reclaimed from something in the house).

Anyway, moving up to 200 was worse. Moved back to 190 and still awful, nothing like the first result. The last full roll of PLA I had was also clear and nothing but trouble. I've always had better luck with ABS. I'd prefer to use PLA now though that the machine is in a main room of the house. I have some colored PLA as well, perhaps I'll give those a try tomorrow.

Anyway, moving up to 200 was worse. Moved back to 190 and still awful, nothing like the first result. The last full roll of PLA I had was also clear and nothing but trouble. I've always had better luck with ABS. I'd prefer to use PLA now though that the machine is in a main room of the house. I have some colored PLA as well, perhaps I'll give those a try tomorrow.

- robotdad

- Posts: 51

- Joined: Thu Sep 09, 2010 7:55 pm

Re: QU-BD Jams

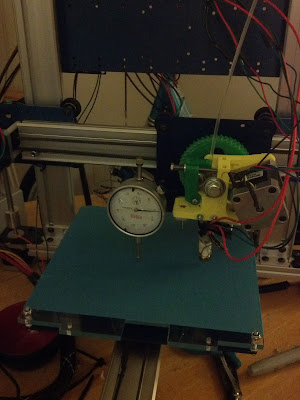

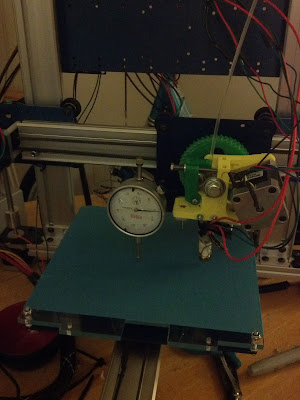

Agree on the leveling front. I made a press-fit adapter for a dial indicator. It bolts to the indicator and gets press-fit onto the side of the extruder platform. Makes leveling effortless. I'm on the road right now, but will upload an STL to thingiverse on Friday.

In the meantime, here are some pics of the setup from when I was doing initial testing off of my cell phone.

In the meantime, here are some pics of the setup from when I was doing initial testing off of my cell phone.

- vgordin

- Posts: 40

- Joined: Mon Dec 24, 2012 6:05 pm

26 posts

• Page 1 of 3 • 1, 2, 3

Return to 3D Printer General Discussion

Who is online

Users browsing this forum: No registered users and 17 guests