Making a Bowden extruder

8 posts

• Page 1 of 1

Making a Bowden extruder

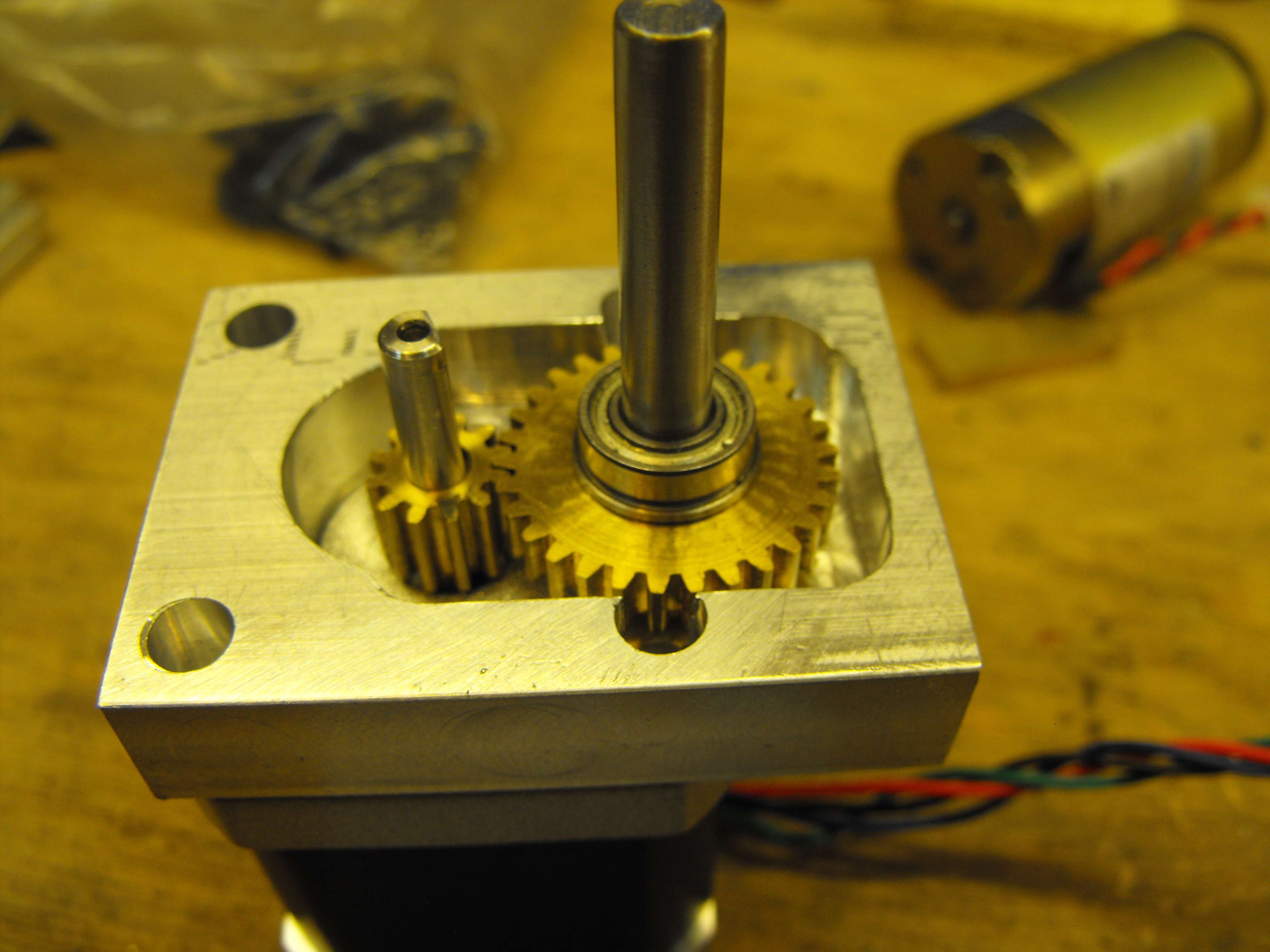

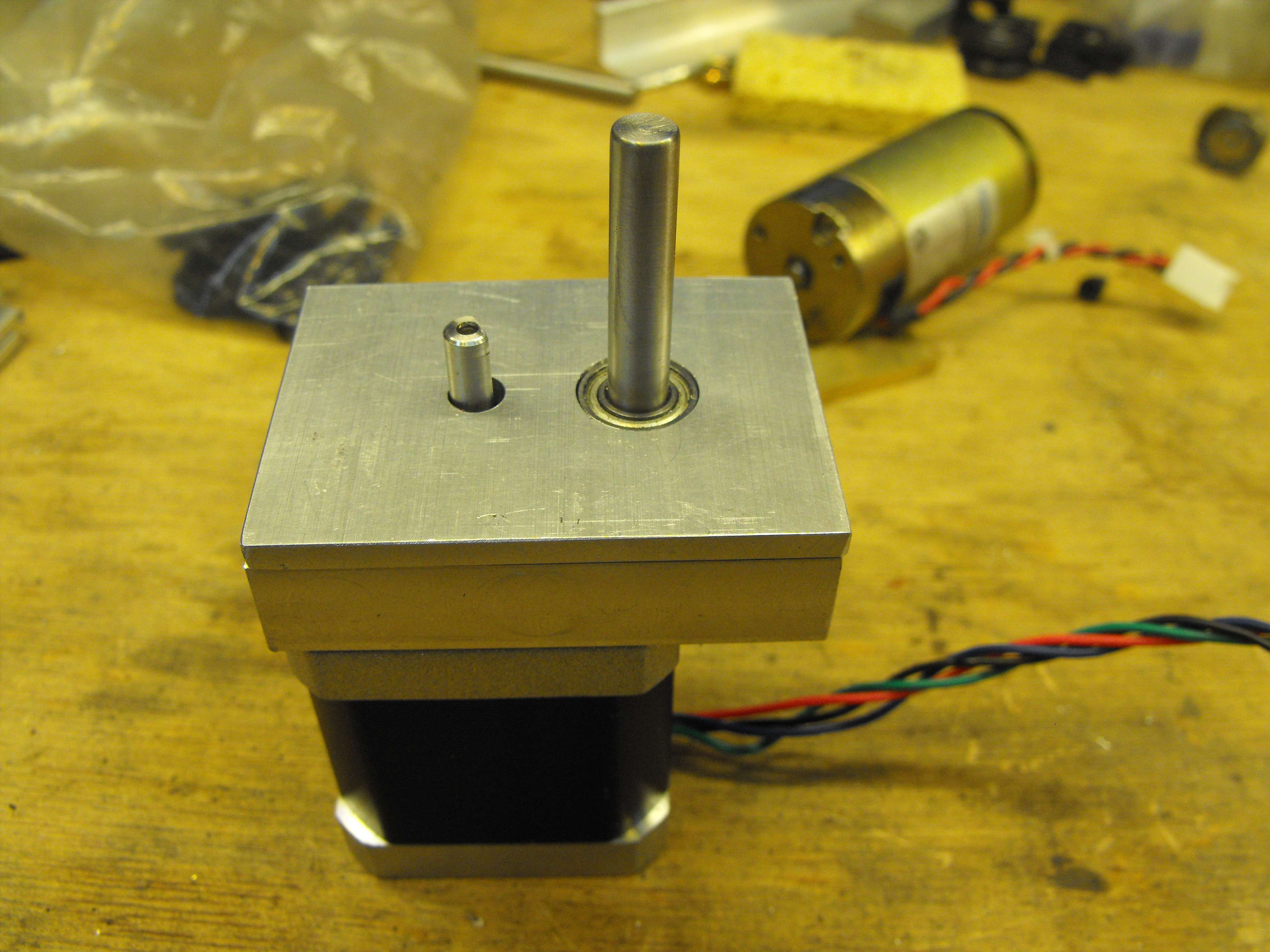

This is going to be my attempt to make a bowden extruder for 1.75 filament from scratch. The motor is one that I got from the QU-BD store that they use on their extruder. It will be geared 2.5 to 1. Let me know if you want more photos as I'm just posting some of the more interesting ones. Some of them are staged as I didn't take any when I was doing the actual operation.

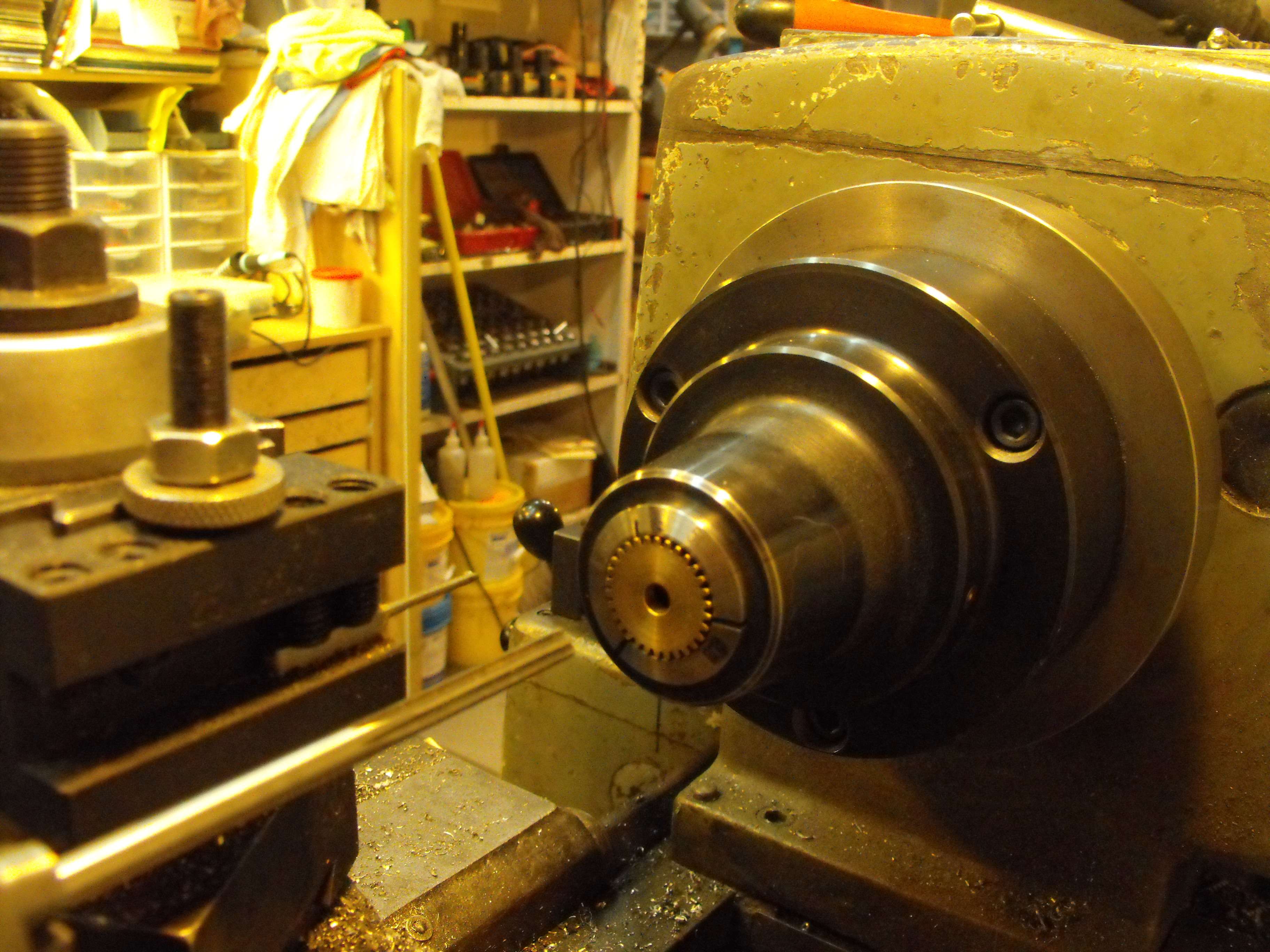

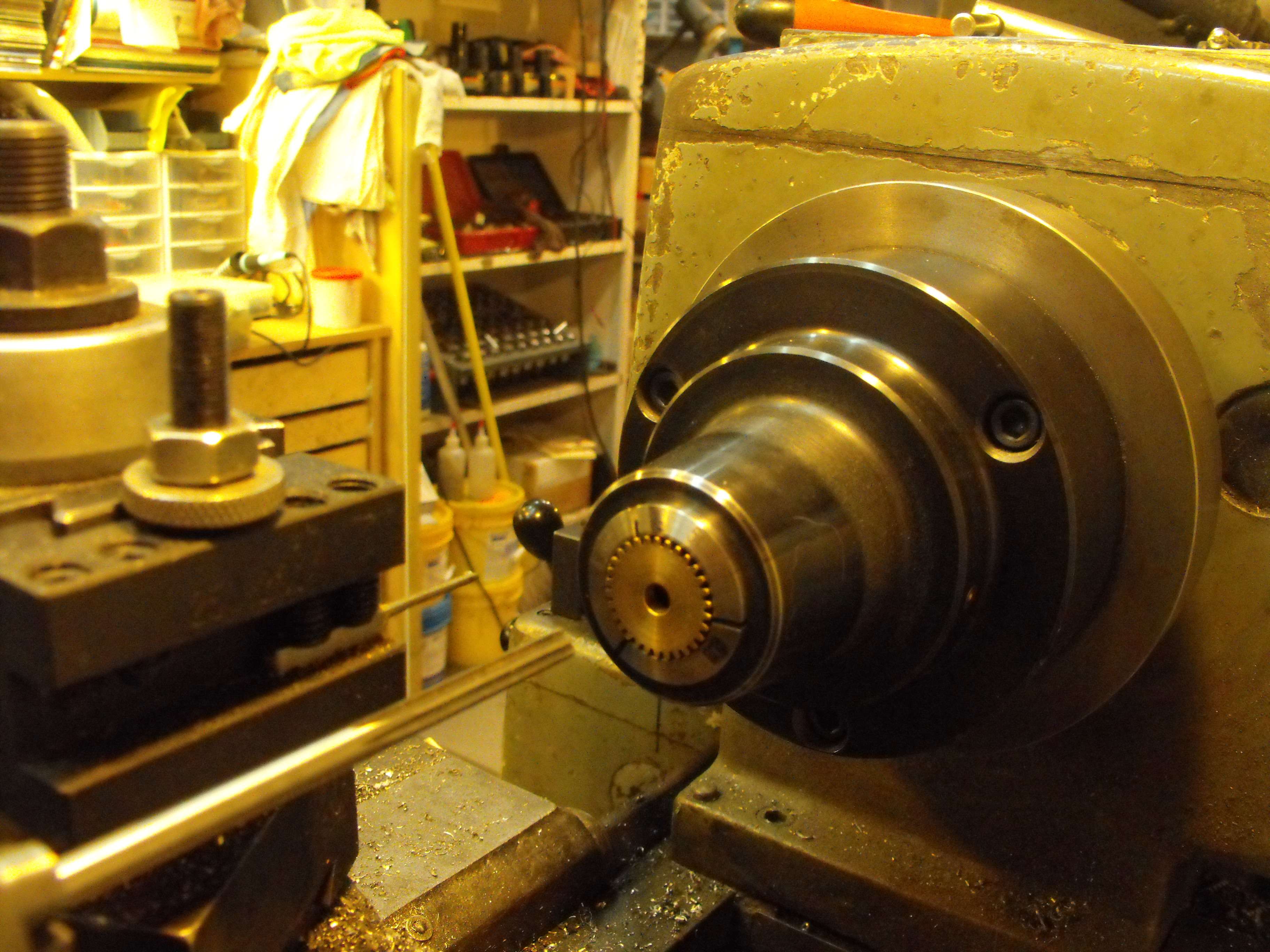

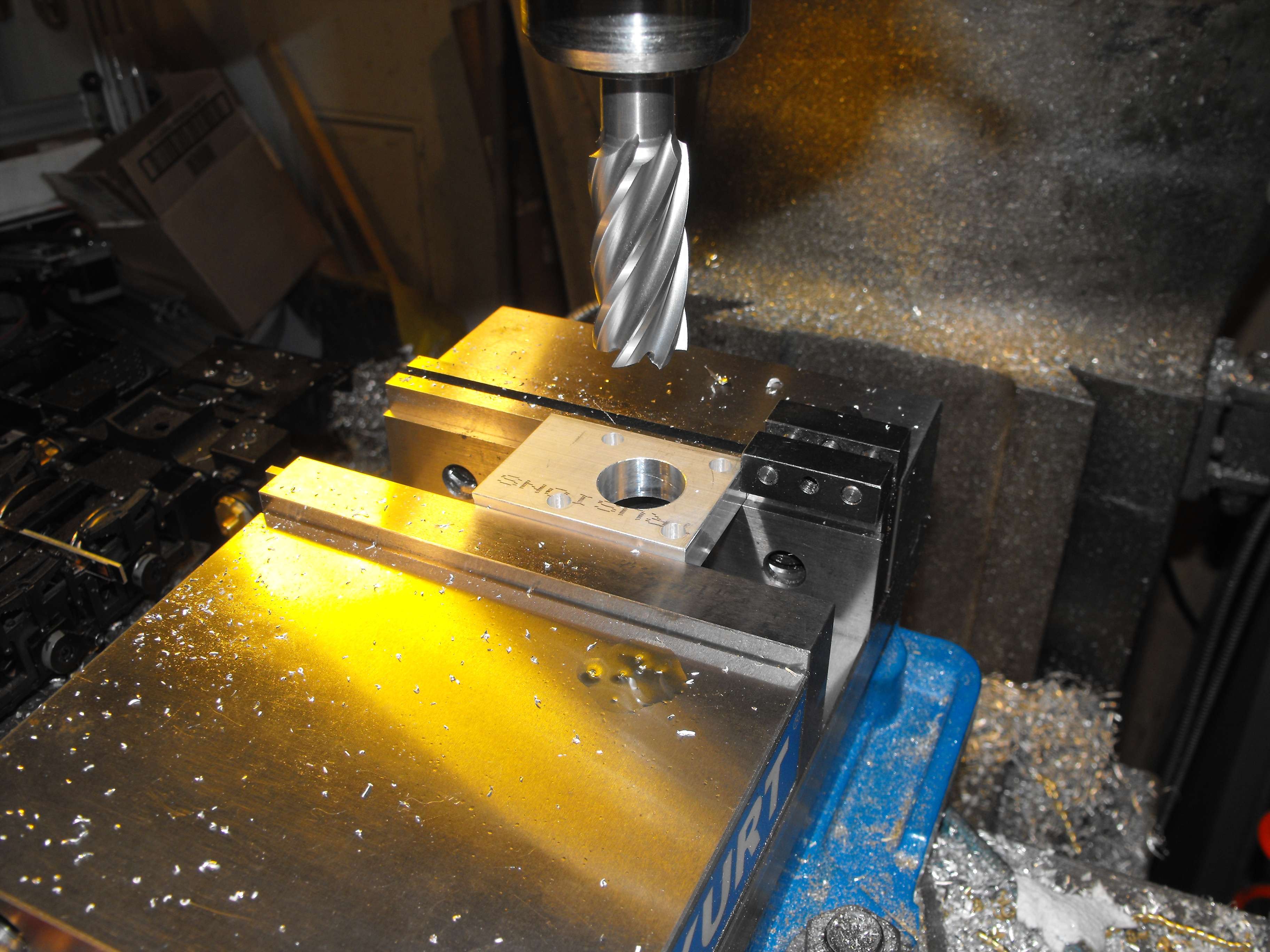

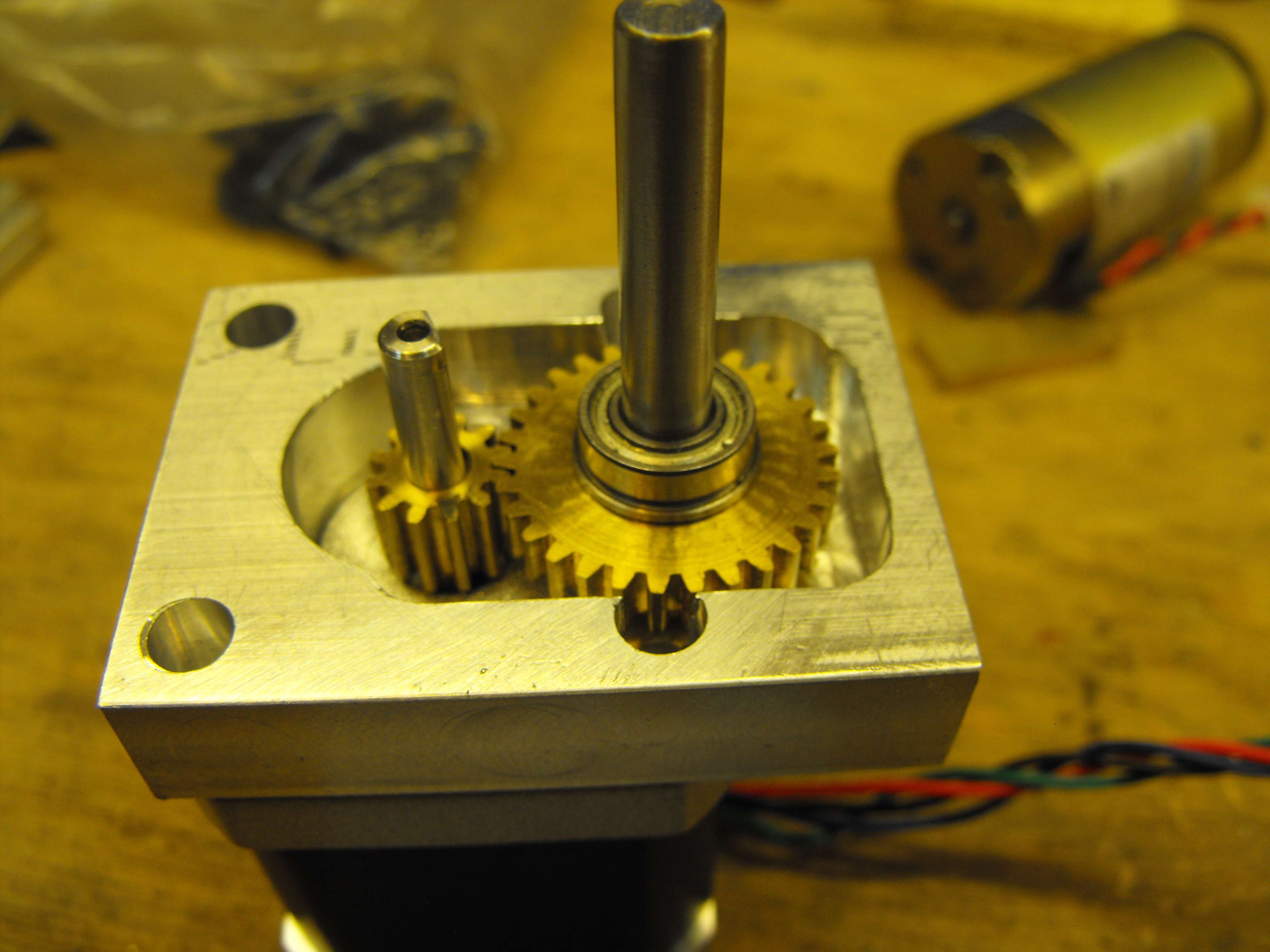

First I made some gear stock. The gears I made are 32 pitch, 12 tooth and 30 tooth for the gearbox.

I then cut the gears from the gear stock.

The gears get bored and reamed.

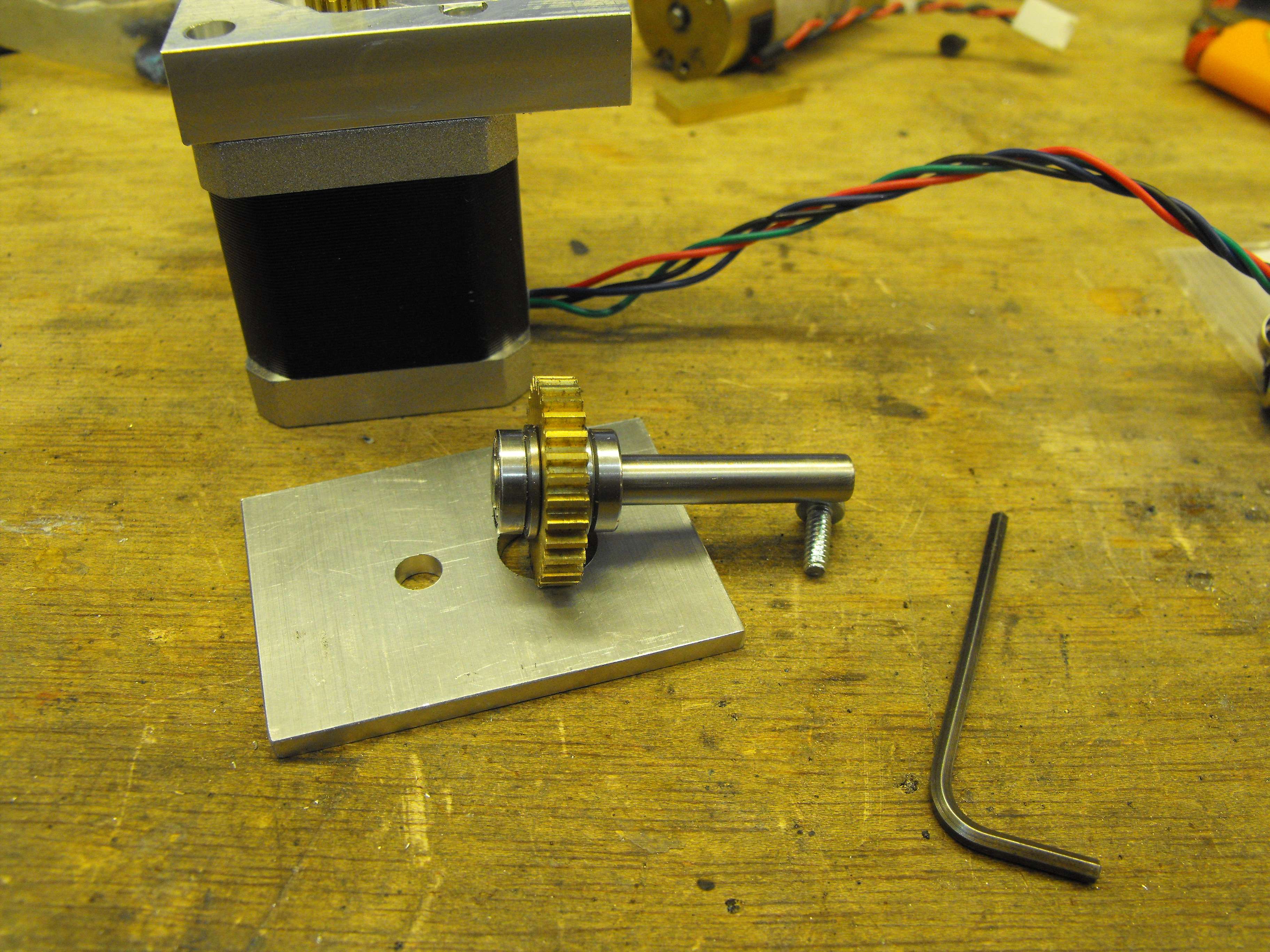

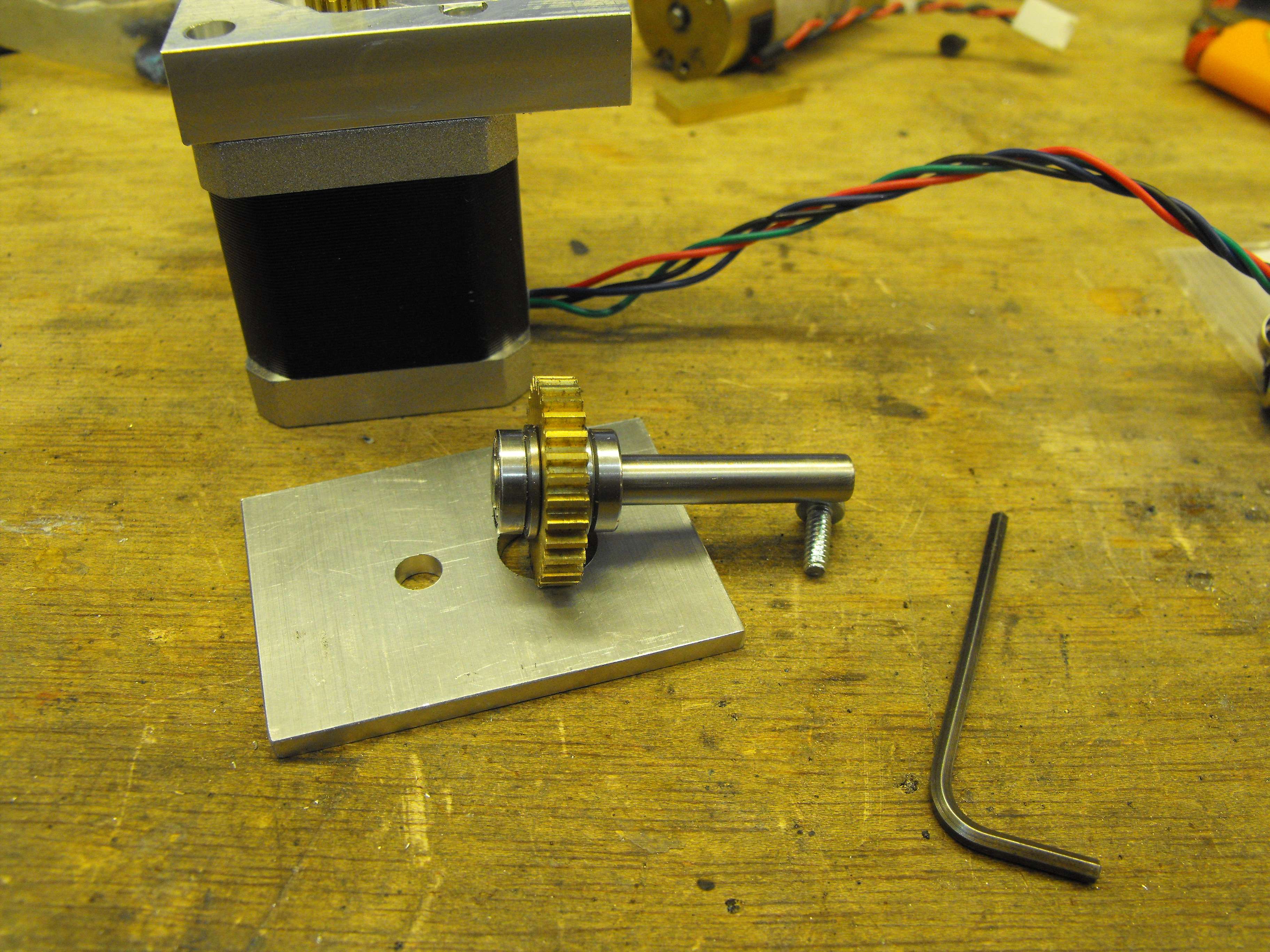

I'm using 303 stainless bearing shaft and knurling it to hold the gear. 2 flanged bearing are added to the shaft.

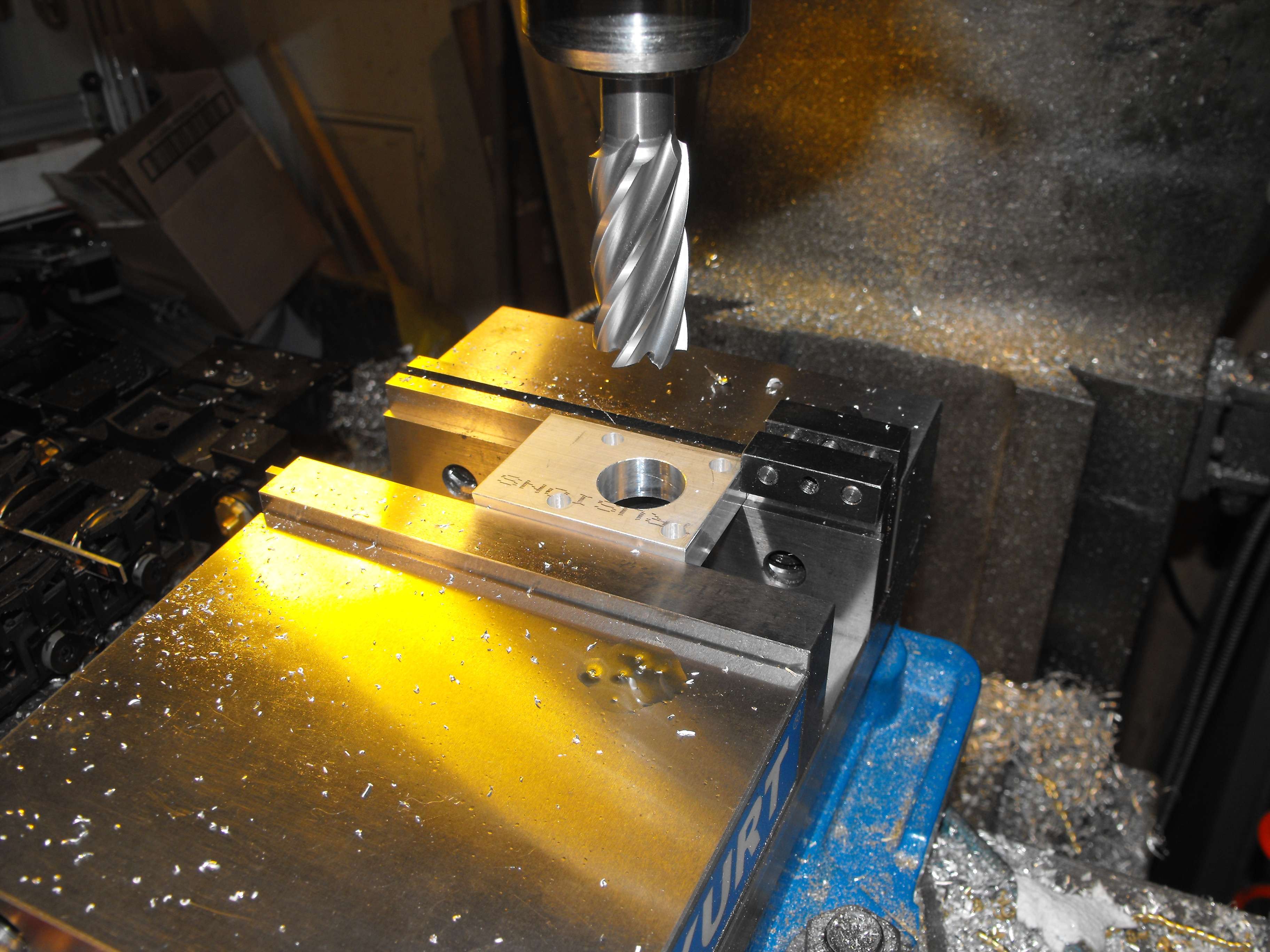

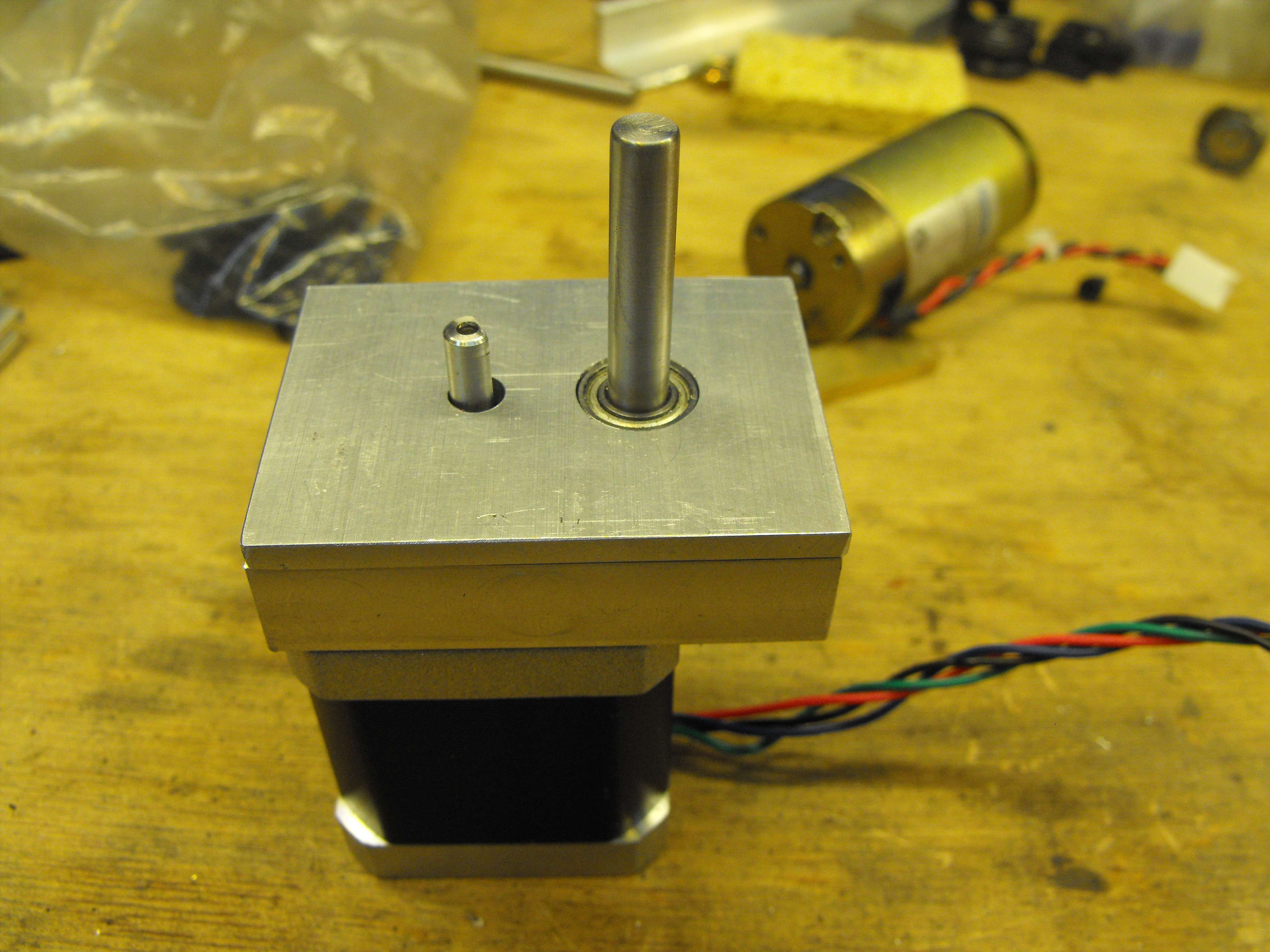

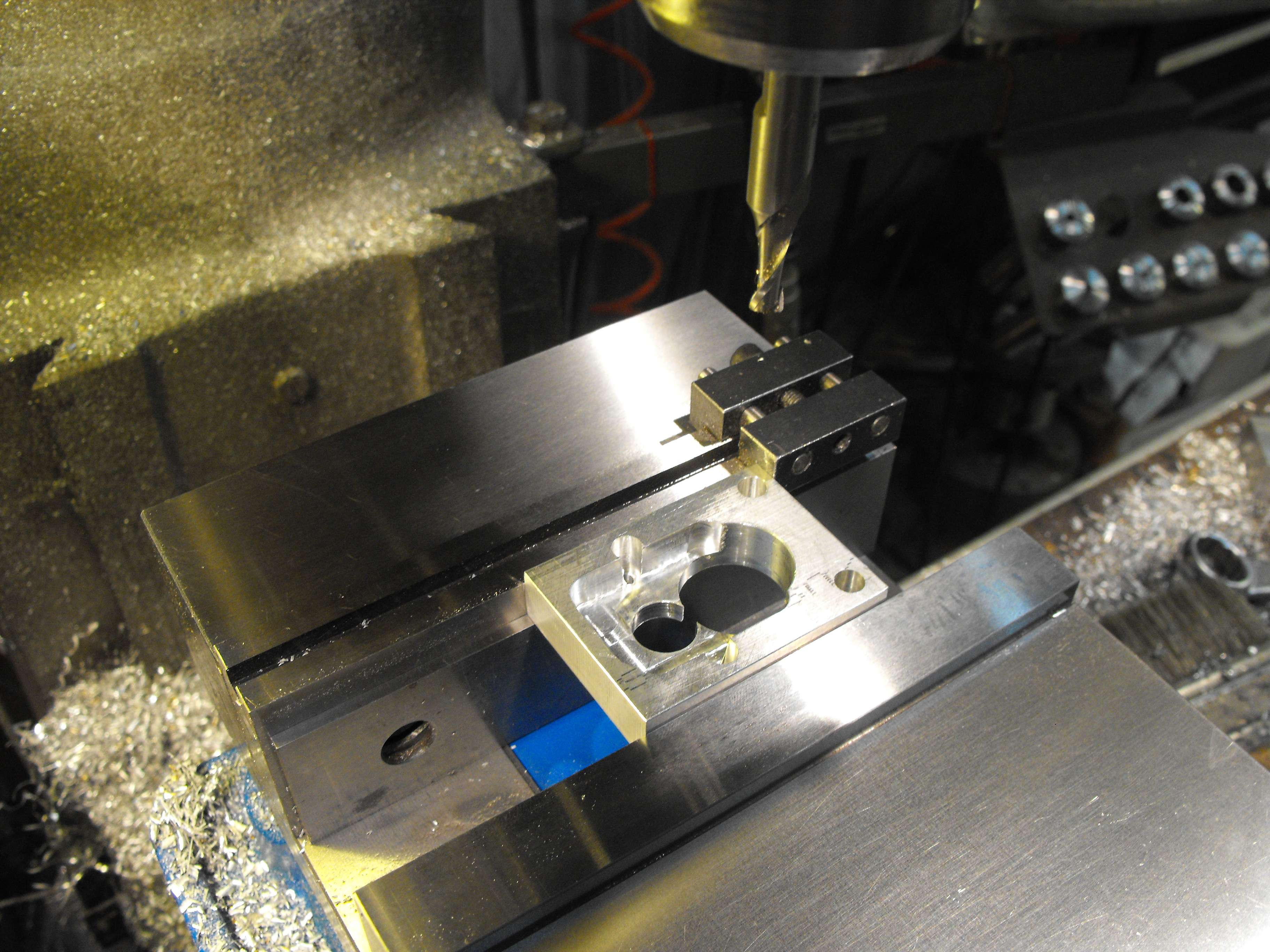

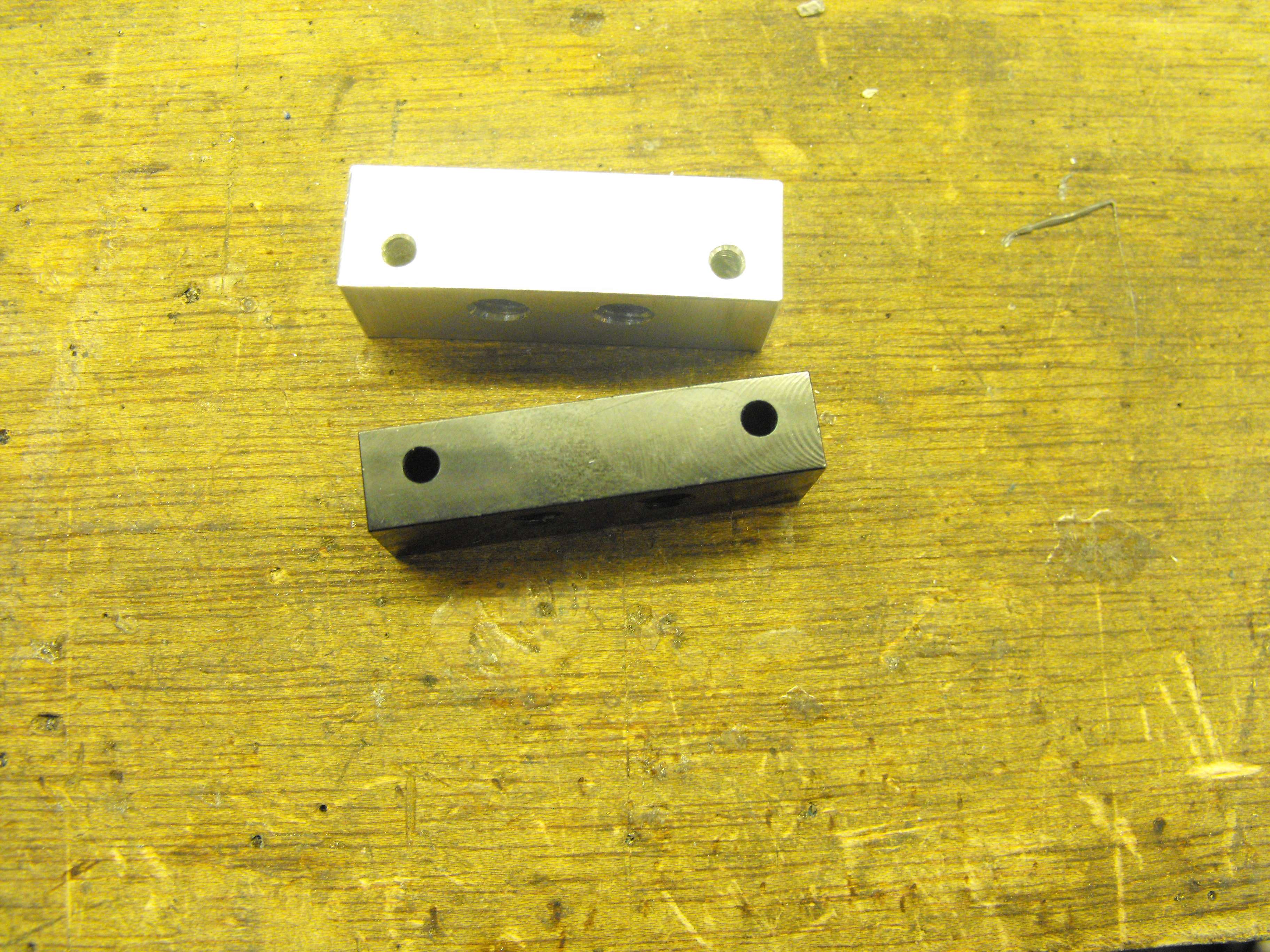

I'm taking a block of alum and making the gearbox.

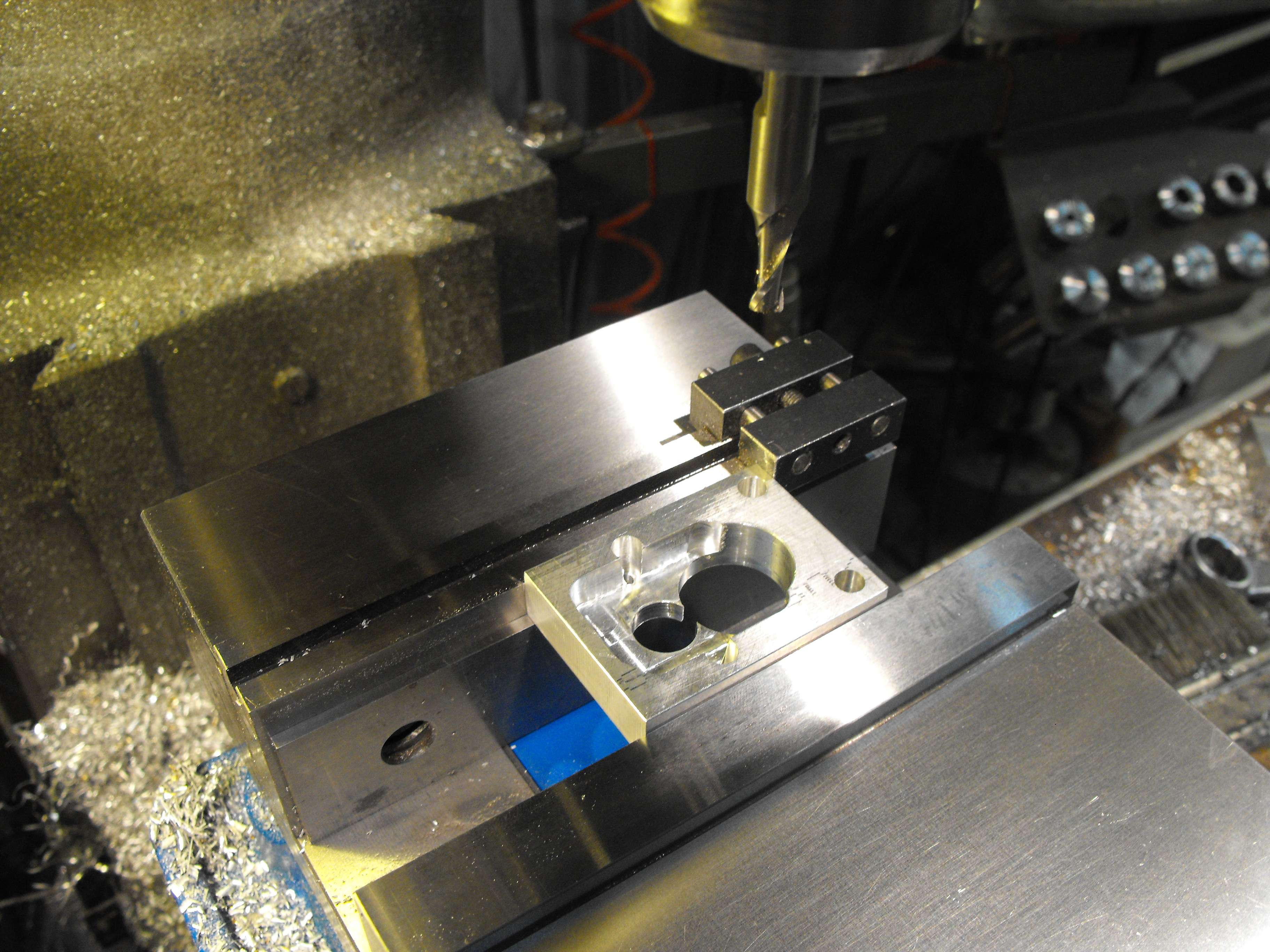

All that is needed to finish is to be drilled and taped for 3mm bolts.

This will be all for now. I need to get some more taps to finish the gearbox. I have some 2mm ID, 4mm OD PFA tubing that I need to figure out how to hold it and will be working on that too.

Rodney

First I made some gear stock. The gears I made are 32 pitch, 12 tooth and 30 tooth for the gearbox.

I then cut the gears from the gear stock.

The gears get bored and reamed.

I'm using 303 stainless bearing shaft and knurling it to hold the gear. 2 flanged bearing are added to the shaft.

I'm taking a block of alum and making the gearbox.

All that is needed to finish is to be drilled and taped for 3mm bolts.

This will be all for now. I need to get some more taps to finish the gearbox. I have some 2mm ID, 4mm OD PFA tubing that I need to figure out how to hold it and will be working on that too.

Rodney

- REdington

- Posts: 57

- Joined: Wed Aug 29, 2012 4:14 am

- Location: Leavenworth Ks

Re: Making a Bowden extruder

Such cool tools you have there. So jealous.

40w Full Spectrum Engineering 5th Gen Hobby 20"x12" w/ Rotary Engraver

South San Francisco Bay Area - Sales and Support Representative for Full Spectrum Engineering

408-47-LASER - Skype: whitelightlaser-thomas - Facebook: White Light Laser

South San Francisco Bay Area - Sales and Support Representative for Full Spectrum Engineering

408-47-LASER - Skype: whitelightlaser-thomas - Facebook: White Light Laser

- TLHarrell

- Posts: 419

- Joined: Thu Jul 28, 2011 11:30 pm

- Location: Morgan Hill, CA

Re: Making a Bowden extruder

TLHarrell wrote:Such cool tools you have there. So jealous.

Thanks Mr Harrell

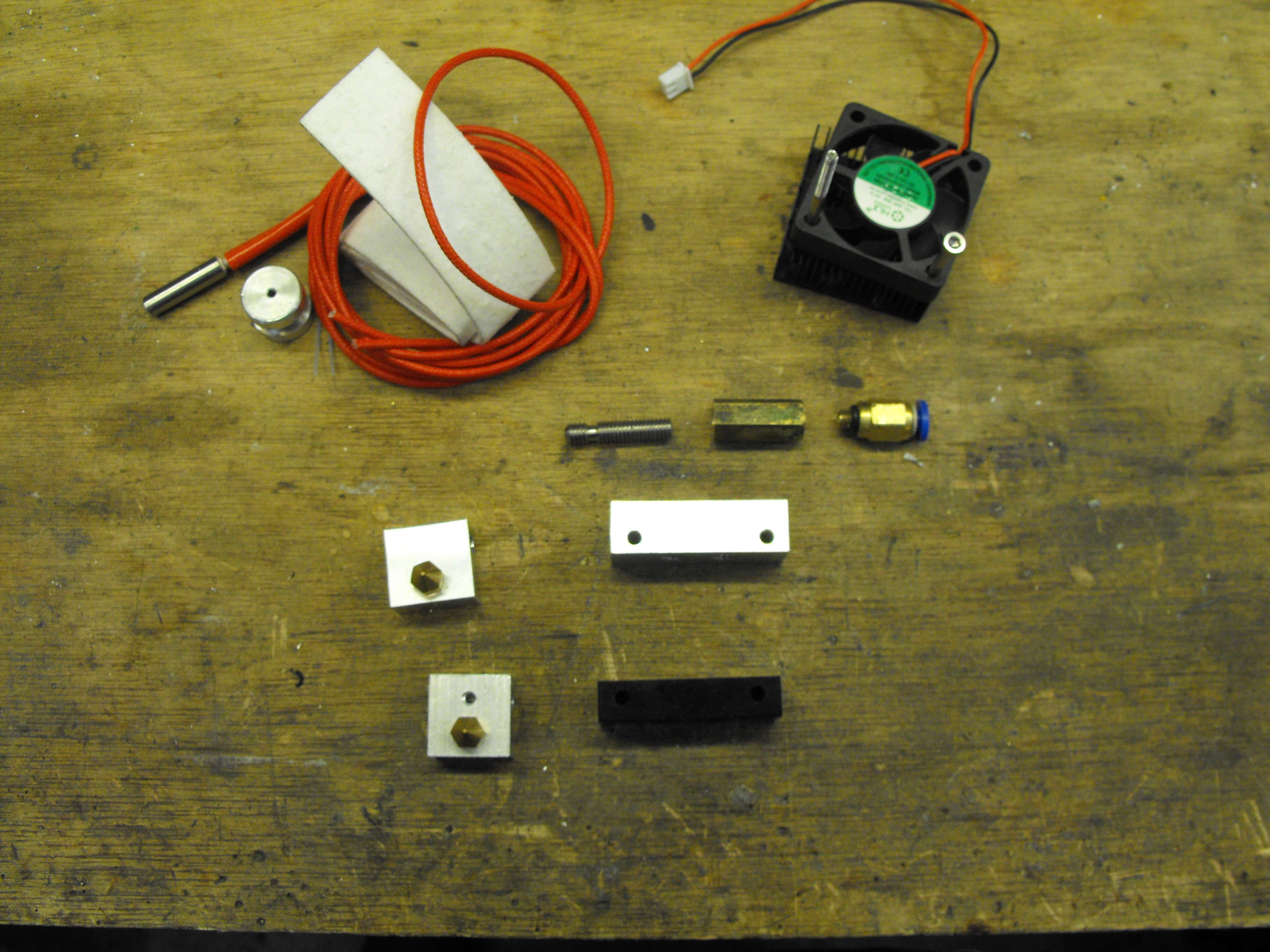

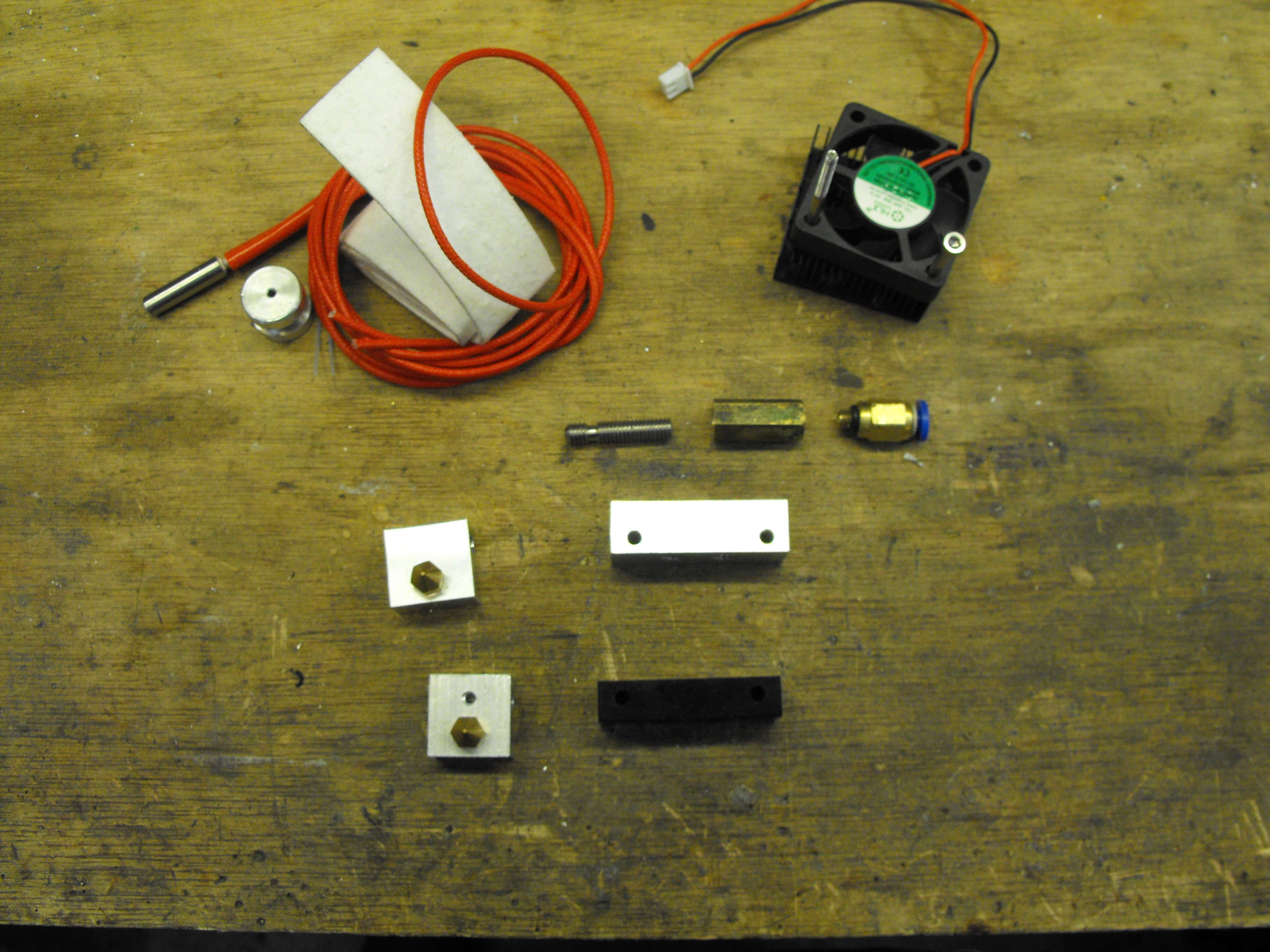

Thanks to Bart for the link to the seemecnc extruders

I ordered some of the extruder without motors and some other parts.

http://shop.seemecnc.com/EZStruder-Extr ... -707XX.htm

I want to try to use the extruder parts on my gearbox and should save me some time.

Rodney

- REdington

- Posts: 57

- Joined: Wed Aug 29, 2012 4:14 am

- Location: Leavenworth Ks

Re: Making a Bowden extruder

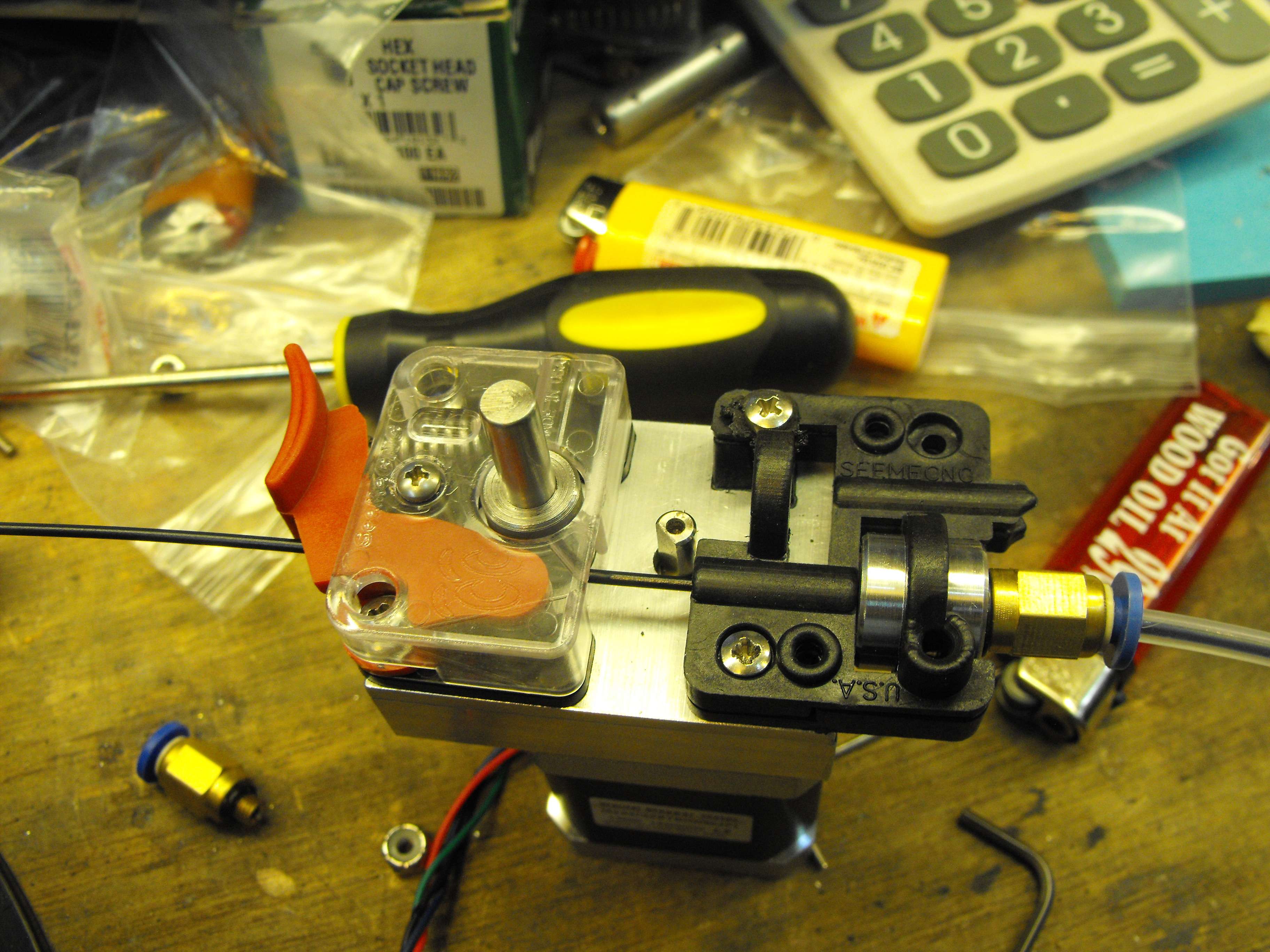

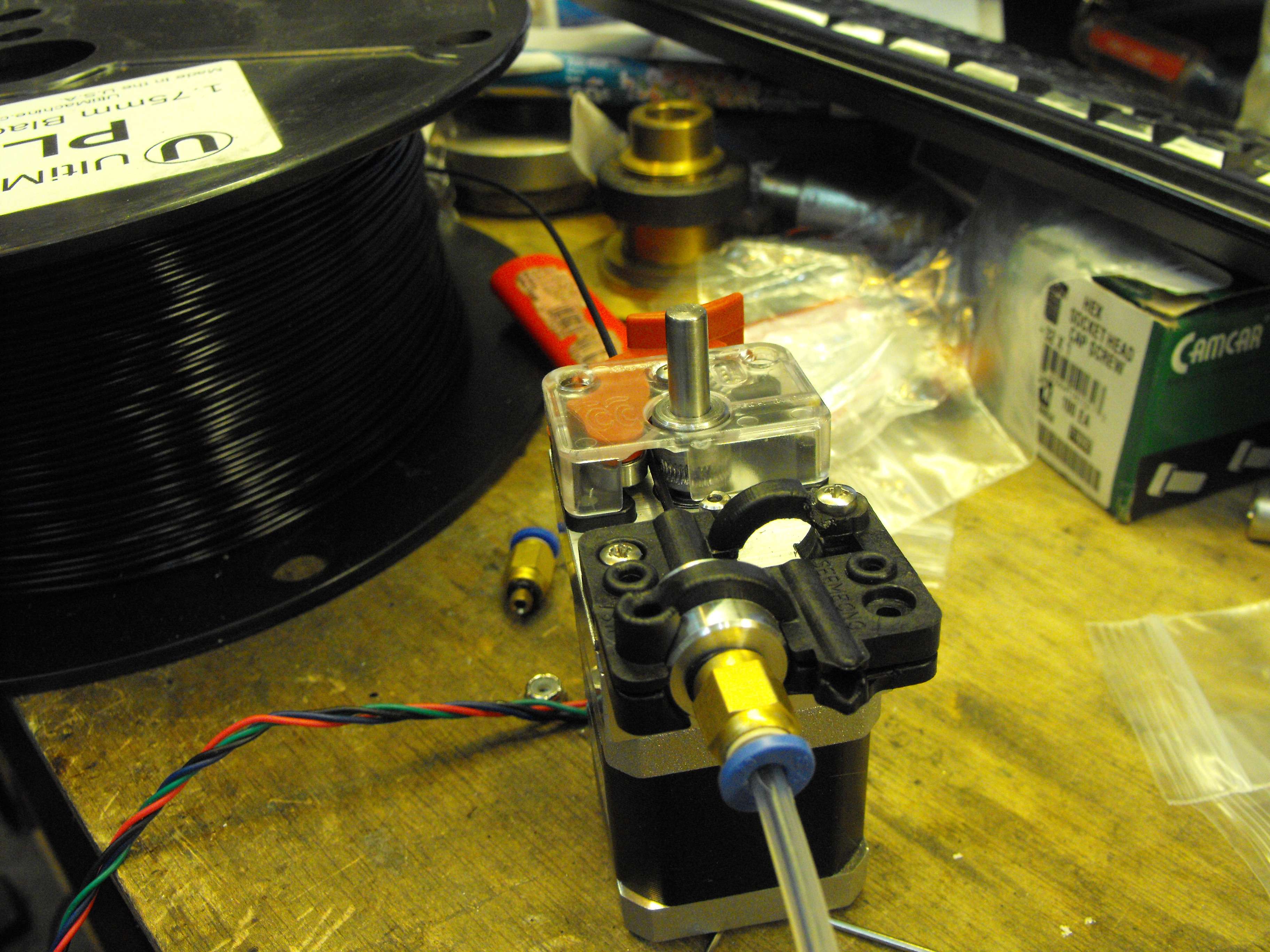

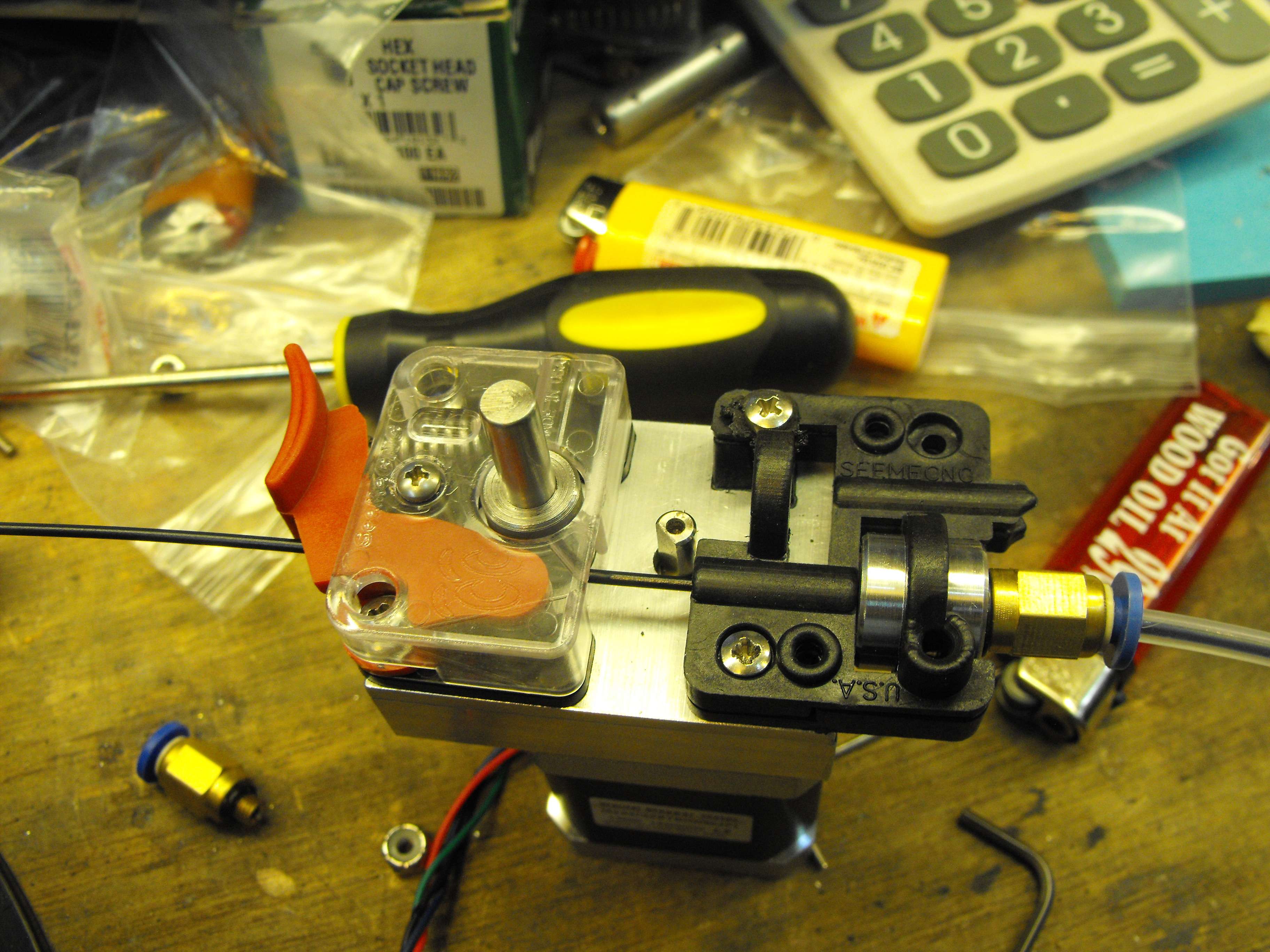

The seemecnc part showed up while I was out on the road (truck driver). I drilled and taped the holes needed in the gearbox for the seemecnc parts and bored and reamed the filament gear for the 1/4" shaft.

I still need to make the mount for the extruder then I'll start on the hotend.

Rodney

I still need to make the mount for the extruder then I'll start on the hotend.

Rodney

- REdington

- Posts: 57

- Joined: Wed Aug 29, 2012 4:14 am

- Location: Leavenworth Ks

Re: Making a Bowden extruder

I had a problem on my large delta where the filament could kink in an unsupported area. Mine was about a 1/4" longer than your area. I just put a hollow nylon spacer there. It would happen on rare occasions, but was pretty difficult to back out when it did.

Bart

"If you didn't build it, you will never own it."

"If you didn't build it, you will never own it."

- bdring

- Site Admin

- Posts: 2966

- Joined: Sun Nov 22, 2009 7:33 pm

- Location: Chicago, IL, USA

Re: Making a Bowden extruder

Semiunrelated, but that's exactly the issue i've got with the "soft" PLA (the flexible stuff) on a Greg's extruder. That's why i've shelved the soft filament until i figure it out.

Might give it another go with a nylon spacer...

Might give it another go with a nylon spacer...

- orcinus

- Posts: 720

- Joined: Tue Feb 14, 2012 4:03 am

Re: Making a Bowden extruder

Thanks for the head up on the flex of the filament. I'll print a guide for it one I have it up and printing (the 300 cube is down for some mods to make it more ridged and I gave the original 200 to my son). This will be mounted on a 200 and tested and then I'll make 2 for the 300 cube.

Rodney

Rodney

- REdington

- Posts: 57

- Joined: Wed Aug 29, 2012 4:14 am

- Location: Leavenworth Ks

Re: Making a Bowden extruder

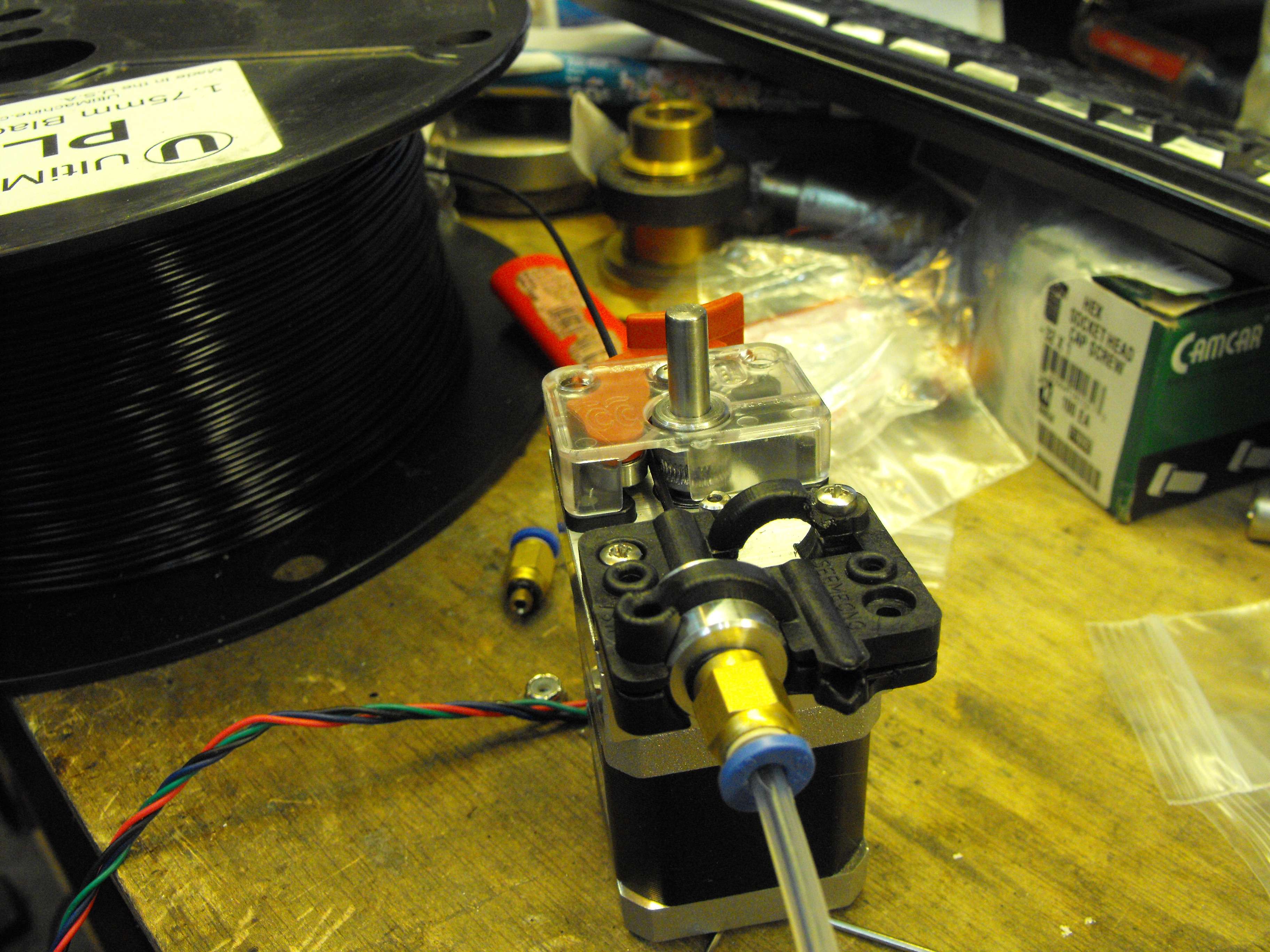

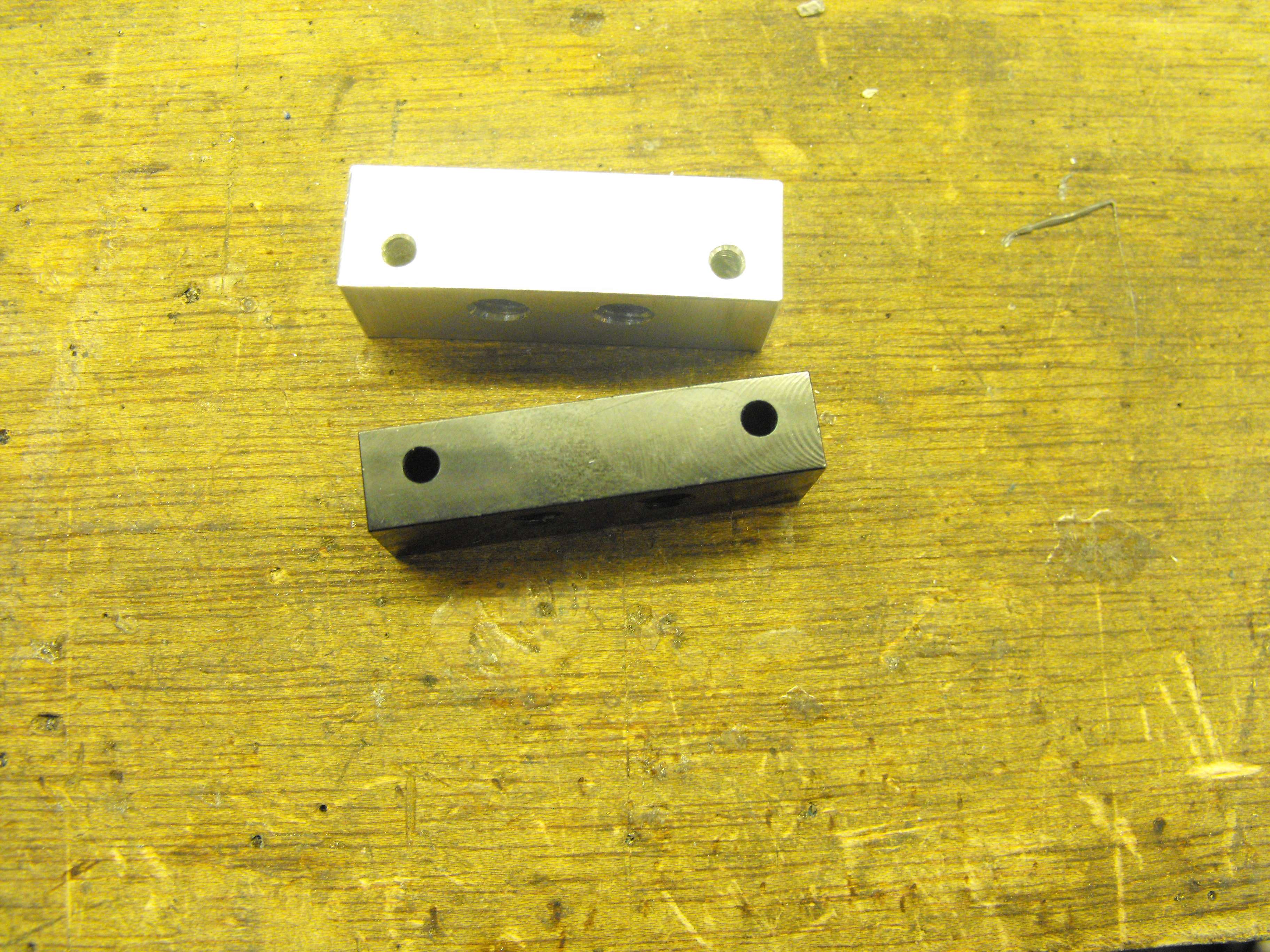

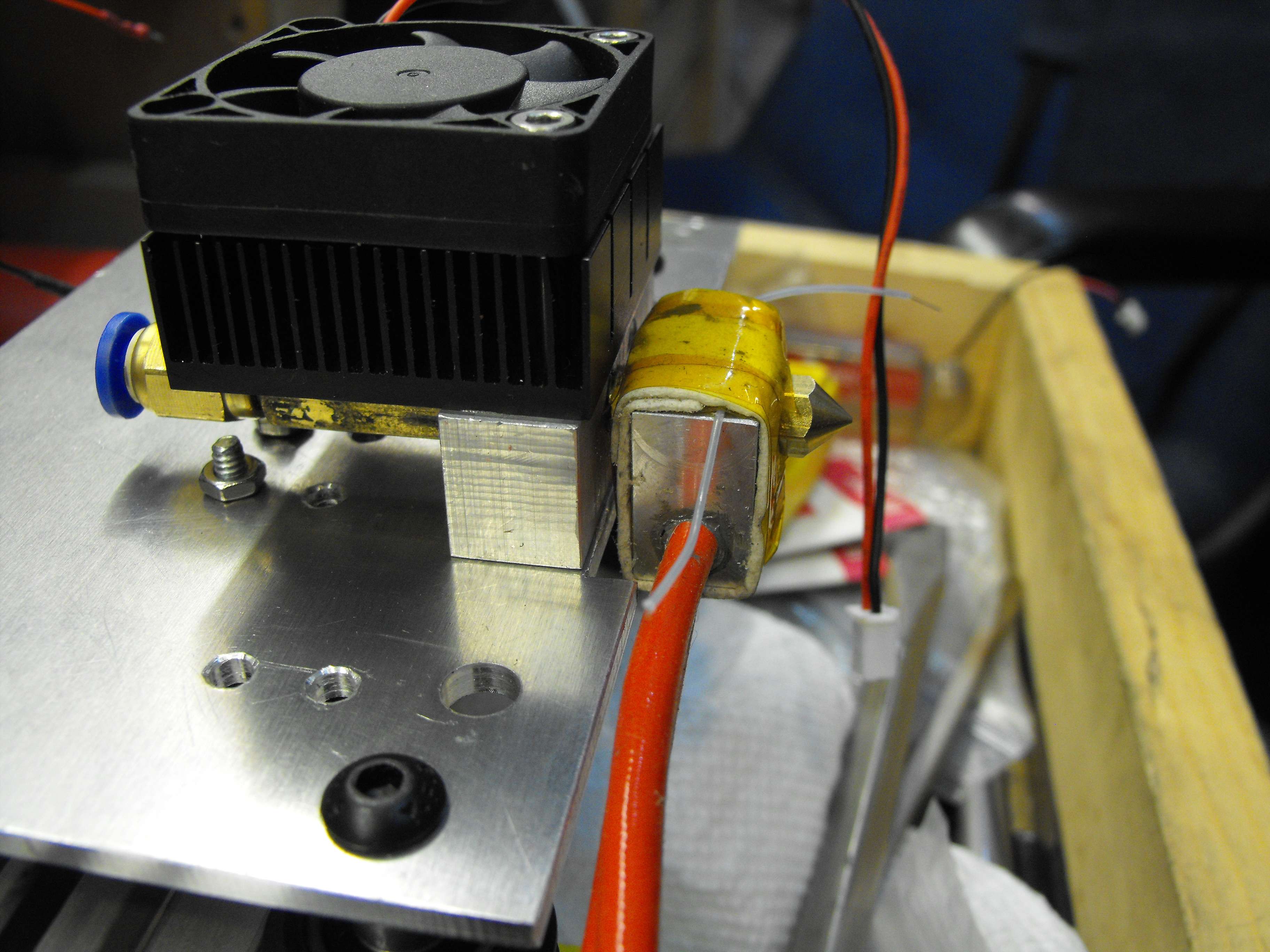

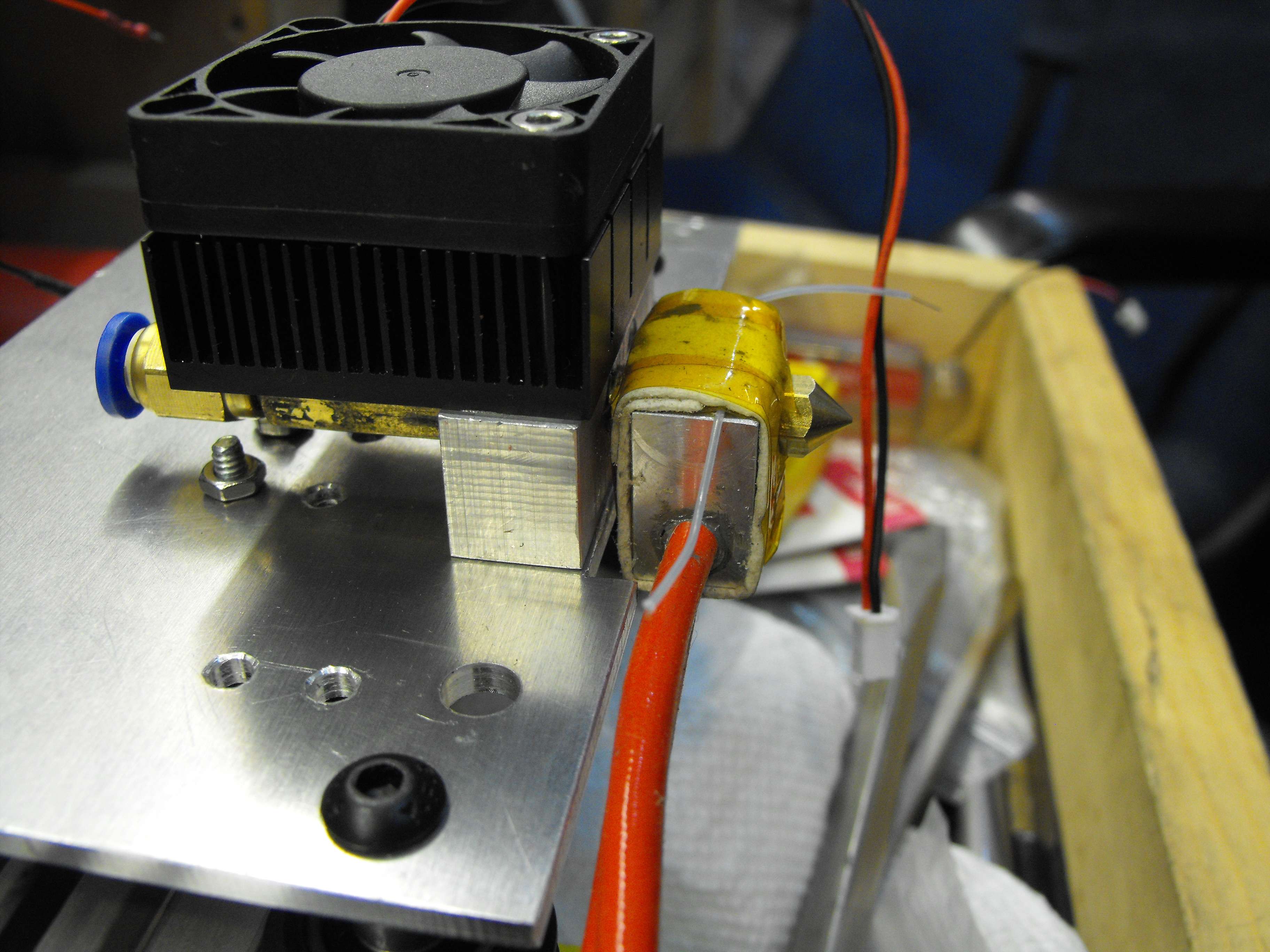

I have the hot-cold end done. I'm using a stock QU-BD barrel and keeping the hotend and coldend very close to try to keep the melt zone close to the same spot. If I have jamming problems, I'll install the PTFE tubing in the barrel. I machined the coldend block larger than the stock QU-BD in hopes to dissipate heat better.

Mounted on the carriage

Rodney

Mounted on the carriage

Rodney

- REdington

- Posts: 57

- Joined: Wed Aug 29, 2012 4:14 am

- Location: Leavenworth Ks

8 posts

• Page 1 of 1

Return to 3D Printer General Discussion

Who is online

Users browsing this forum: No registered users and 4 guests